Welcome to “Rumtoo” Plastic Recycling Machinery, where high-quality PP/PE film recycling machinery is our top priority. Our machines are designed with the features of easy operation, easy maintenance, and reasonable prices. Our experienced engineers are ready to provide you with detailed operation manuals, technical documents, and timely after-sales service.

At the same time, we also provide free product design services. We are committed to customizing production solutions for customers, making production more efficient and environmentally friendly, thereby forming the core competitiveness of sustainable development and contributing to global energy conservation, emission reduction, and green economic development, striving to create a better life.

Our products include: plastic recycling lines, plastic washing lines, shredders, crushers, compaction granulation systems, and film extruders.

Customers are our respected employers, and your requirements will be fully respected here.

Our Approach

OUR MISSION IS TO BE THE BEST IN PLASTIC RECYCLING MACHINERY INDUSTRY!

A FULL SERVICE

Dedicated Team

Best Engineers

24/7 Supports

Company Vision

Advancing the Future of Plastic Recycling

We provide a full range of services, including preliminary design, manufacturing, after-sales service, etc.

MEET OUR TEAM

EXCHANGE FRESH THINKING AND

EMBRACE NEW TECHNOLOGIES

This letter is to inform you that our supplier has been a very good supplier. In our many dealings with them, we have found them to be reliable and trustworthy and we highly recommend them to you as a supplier.

MR. DAMIAN FLEGEL

CEOI confirm that our company in Australia has worked with Rumtoo for over five years and are very happy torecommend them for your requirements. We are very impressed with their fast service and quality equipment.

Maria Flynn

DR. ADRIAN SANCHEZ ROAThis trade reference letter is to confirm that we have purchased equipment from Rumtoo and found them to be very easy to work with, professional and trustworthy. We would certainly work with them again on future equipment purchases and higher recommend them to others.

Gina Kennedy

MARK R.ALT,PE Director of EngineeringOUR PRODUCTS

KEEP ALWAYS UPDATED WITH

OUR FRESH BLOG AND PRODUCT POSTS

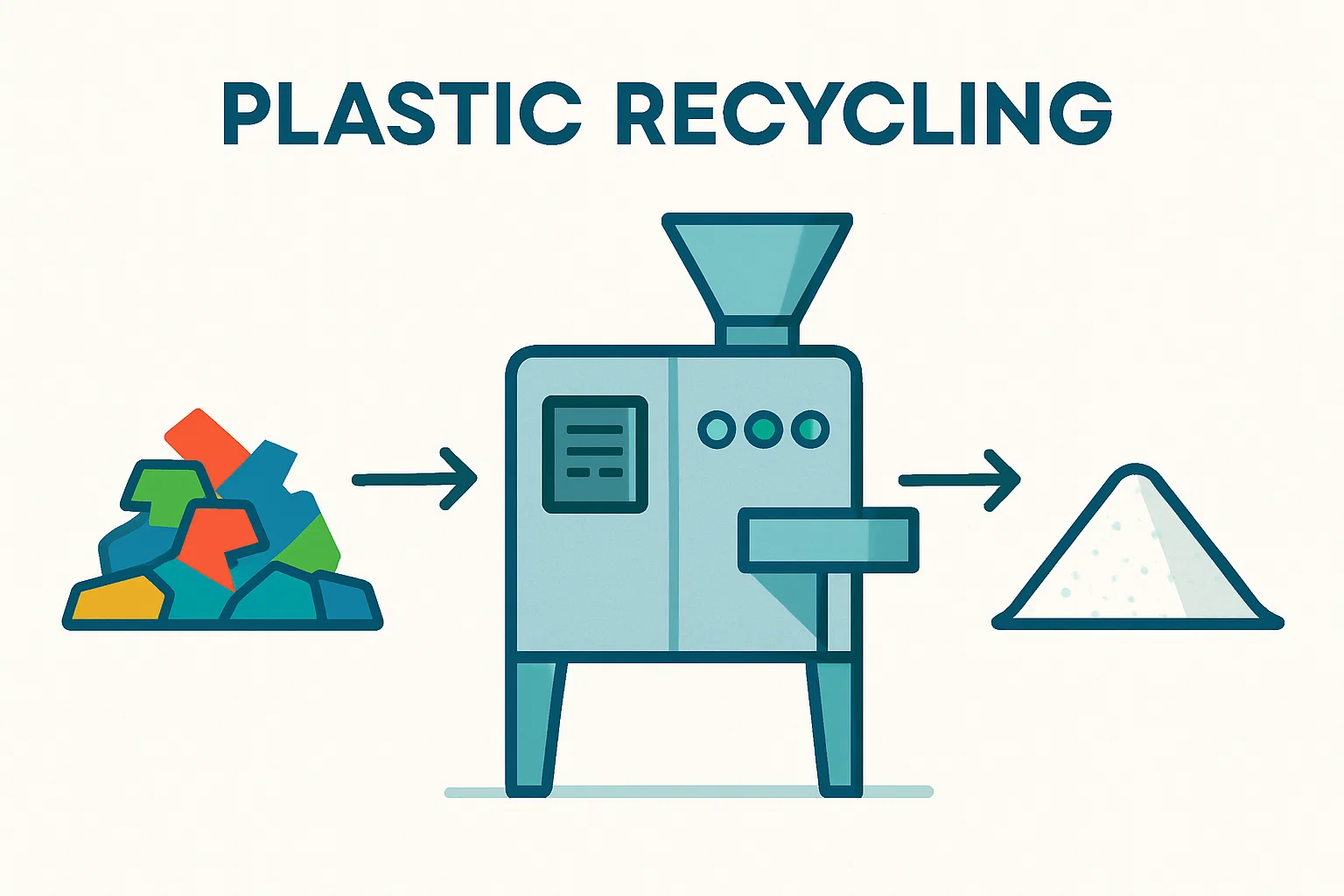

Plastic powder is a vital material in modern manufacturing, utilised across industries from injection moulding to 3D printing and rotational moulding. For recycling professionals and manufacturers in the USA and Europe, understanding how to produce high-quality plastic powder is crucial to improving cost efficiency, sustainability, and product consistency.

Rumtoo Machine, a leader in innovative plastic recycling equipment, offers advanced solutions tailored for transforming plastic waste into fine powder. In this guide, we will break down the entire process of making plastic powder, from material selection to machine operation.

What Is Plastic Powder and Why Is It Important?

Plastic powder refers to finely ground particles of plastic material, typically ranging from 30 to 500 microns. It is used extensively in various industries due to its easy handling, uniform flow, and compatibility with automated production systems.

Key Applications of Plastic Powder

- Injection Moulding

- Rotational Moulding

- 3D Printing

- Coatings and Surface Finishing

- Recompounding and Extrusion

Producing your own plastic powder can significantly reduce raw material costs and promote a circular manufacturing process.

Step-by-Step Process: How to Make Plastic Powder

1. Selecting the Right Raw Material

The quality of your plastic powder starts with the feedstock. Choose clean, sorted plastic scrap—common types include:

- PVC (Polyvinyl Chloride)

- PE (Polyethylene)

- PP (Polypropylene)

- PET (Polyethylene Terephthalate)

- ABS (Acrylonitrile Butadiene Styrene)

Rumtoo Machine recommends pre-sorted and washed materials for optimal performance.

2. Pre-Processing: Shredding and Granulation

Before pulverisation, plastic waste must be reduced to manageable sizes:

- Shredding: Converts bulky waste into smaller flakes.

- Granulation: Further reduces flake size to prepare for pulverising.

Equipment Highlight: Rumtoo Machine offers high-speed granulators designed for consistent particle sizing.

3. Pulverising: Turning Granules into Powder

This is the core process. Using a plastic pulveriser, granules are ground into fine powder. Key parameters include:

- Speed and Blade Configuration

- Cooling System (to avoid material degradation)

- Mesh Size (for desired powder fineness)

Recommended Equipment: Fully Automatic PVC Pulverizer by Rumtoo Machine ensures high throughput and precision.

4. Sieving and Classification

To ensure uniform particle size distribution, powder is passed through vibratory sieves:

- Removes oversized particles

- Ensures batch consistency

- Supports downstream automation

5. Collection and Packaging

Once sieved, plastic powder is collected in hoppers or bags using dust-free systems. Proper labelling ensures traceability for industrial use.

Types of Plastic Pulverising Equipment

Disc Mill Pulverisers

Ideal for rigid plastics like PVC. Offers high-speed rotation and superior control.

Cryogenic Pulverisers

Uses liquid nitrogen to freeze plastics before grinding, perfect for heat-sensitive materials like TPU or rubber compounds.

Turbo-Type Pulverisers

Efficient and fast, turbo models are suitable for high-volume operations with precision control.

Rumtoo Machine provides all three types, helping clients select the right machine based on material type, volume, and fineness requirements.

Benefits of Producing Plastic Powder In-House

- Cost Savings on raw material procurement

- Quality Control over particle size and purity

- Waste Reduction through full recycling of in-house scrap

- Environmental Compliance with EU and US sustainability regulations

Rumtoo Machine’s equipment is CE and ISO certified, ensuring compatibility with regulatory requirements.

Equipment Workflow Diagram

Performance Comparison Chart

| Machine Type | Material Suitability | Output Capacity | Powder Fineness | Cooling System |

|---|---|---|---|---|

| Disc Mill | Rigid PVC, PE | Medium | 200-300 microns | Air or Water |

| Cryogenic | TPU, Rubber, Nylon | Low | <100 microns | Liquid Nitrogen |

| Turbo Mill | PP, ABS, PET | High | 150-250 microns | Integrated Air |

Frequently Asked Questions (FAQ)

Q1: Can I process mixed plastic waste into powder?

A1: It is recommended to separate plastics by type for best results. Mixed plastics may yield inconsistent powder quality.

Q2: How fine can Rumtoo Machine’s pulverisers grind plastic?

A2: Our machines can achieve particle sizes as low as 50 microns, depending on material and configuration.

Q3: What is the power consumption of a standard pulveriser?

A3: Power usage varies, but typically ranges from 40kW to 90kW depending on machine size and throughput.

Q4: Are your machines suitable for 24/7 industrial operation?

A4: Yes, Rumtoo Machine designs all systems for continuous, industrial-grade usage with minimal downtime.

Why Choose Rumtoo Machine for Your Plastic Powder Production?

Rumtoo Machine combines engineering excellence with years of experience in plastic recycling. Our plastic recycling equipment is trusted by manufacturers across Europe and the USA for its durability, innovation, and precision.

Key Advantages:

- Turnkey solutions for plastic powder production

- Customisable systems for varied material types

- Full technical support and installation service

- Efficient after-sales support and parts availability

Ready to Start Making High-Quality Plastic Powder?

If you’re looking to invest in reliable, high-performance plastic recycling equipment, Rumtoo Machine is here to help. Contact us today to discuss your project or request a quote for a tailored solution.

Join the leaders in sustainable manufacturing—partner with Rumtoo Machine today.