Ciptakan Nilai Tinggi, Pelet Plastik Seragam

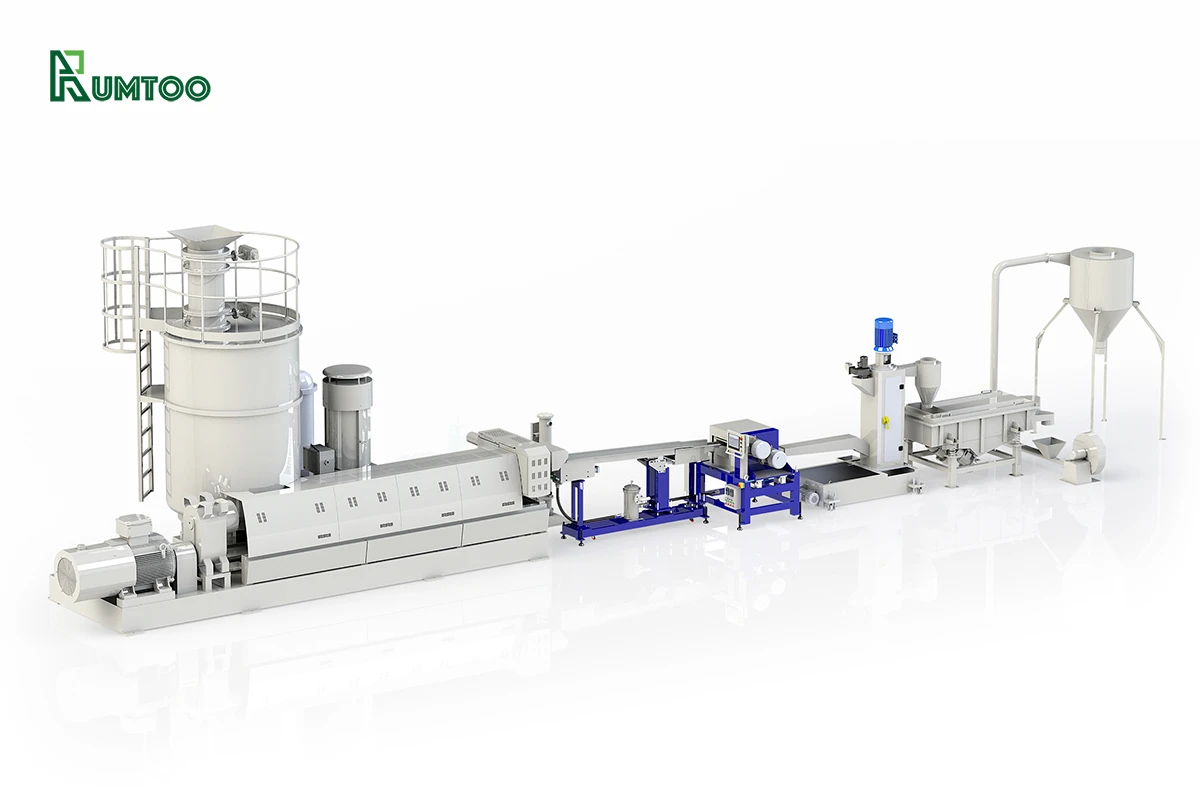

Lini pelet plastik canggih kami merupakan langkah terakhir dalam mengubah sampah plastik daur ulang menjadi bahan baku yang bernilai, konsisten, dan dapat digunakan kembali. Kami merancang sistem lengkap untuk meracik, memodifikasi, dan membuat pelet berbagai macam polimer.

Rancang Lini Pelet Anda

Memilih Sistem Pelet yang Tepat

Teknologi ideal bergantung pada jenis material, kebutuhan output, dan preferensi operasional Anda. Kami berspesialisasi dalam dua sistem utama yang sangat efisien.

Jalur Pelet Untai Air

Metode klasik, kuat, dan hemat biaya yang ideal untuk berbagai macam polimer, terutama yang sensitif terhadap perubahan suhu.

- Proses: Plastik cair diekstrusi menjadi untaian, didinginkan dalam penangas air, lalu dipotong menjadi pelet dengan granulator.

- Terbaik untuk: PET, Polistirena (PS), dan senyawa yang sangat terisi atau diperkuat.

- Keuntungan: Pengoperasian yang sederhana, mudah dibersihkan, dan serbaguna untuk laboratorium atau produksi berskala besar.

Lini Pelet Cincin Air

Sistem yang lebih otomatis dan ringkas yang memotong pelet pada permukaan cetakan, ideal untuk produksi poliolefin bervolume tinggi.

- Proses: Pisau berputar pada permukaan cetakan, memotong pelet yang langsung padam dan diangkut oleh cincin air yang bersirkulasi.

- Terbaik untuk: PE, PP, dan bahan lain dengan viskositas leleh yang lebih rendah.

- Keuntungan: Menghasilkan pelet yang seragam dan bulat, membutuhkan lebih sedikit ruang lantai, dan sangat otomatis.

Lihat Sistem Kami Beraksi

Saksikan panduan lengkap salah satu lini produksi pelet plastik canggih kami, dari bahan mentah hingga pelet akhir berkualitas tinggi.

Direkayasa untuk Kualitas Pelet Terbaik

Setiap komponen dipilih untuk memastikan kemurnian, konsistensi, dan nilai produk akhir Anda.

-

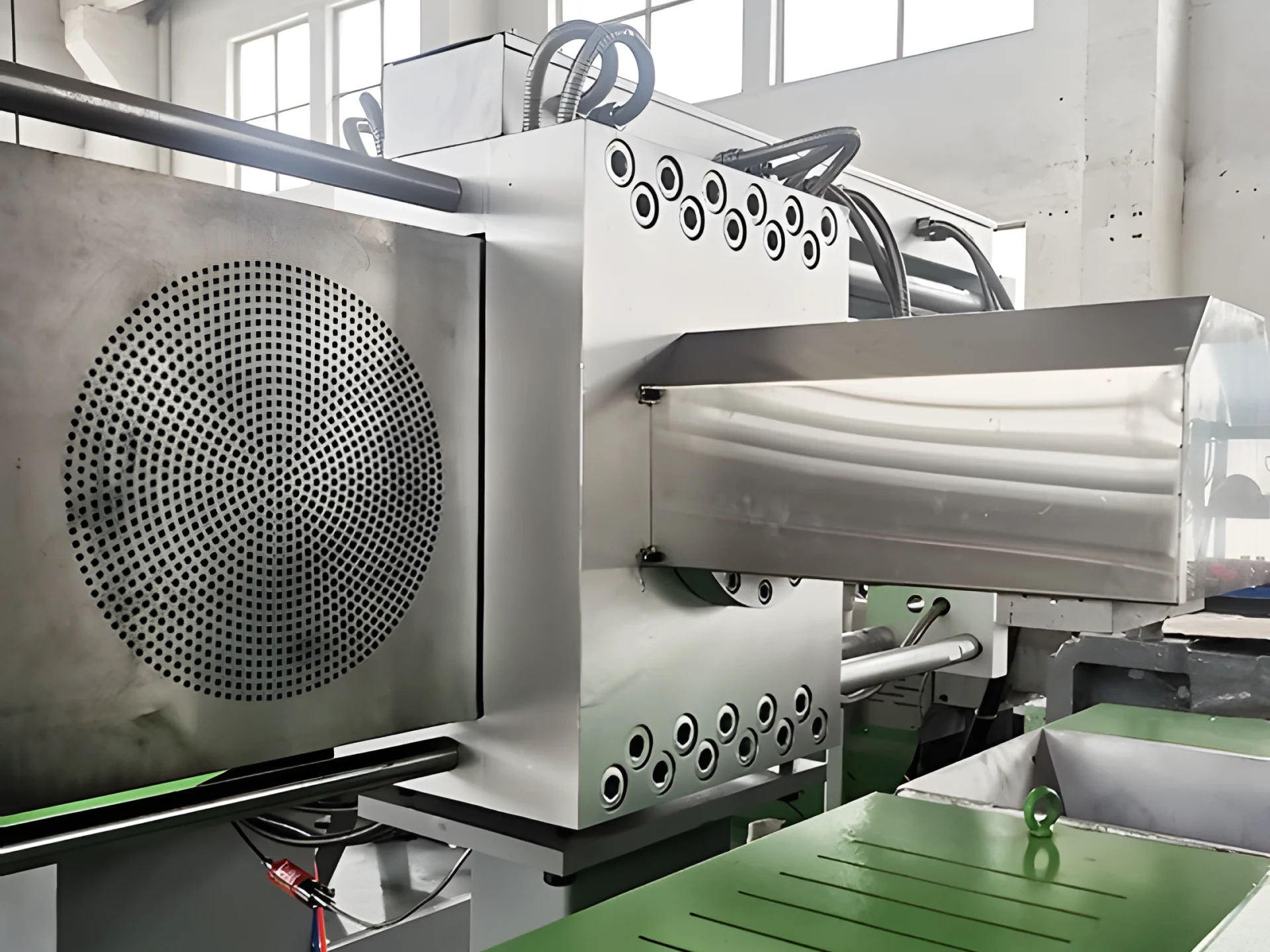

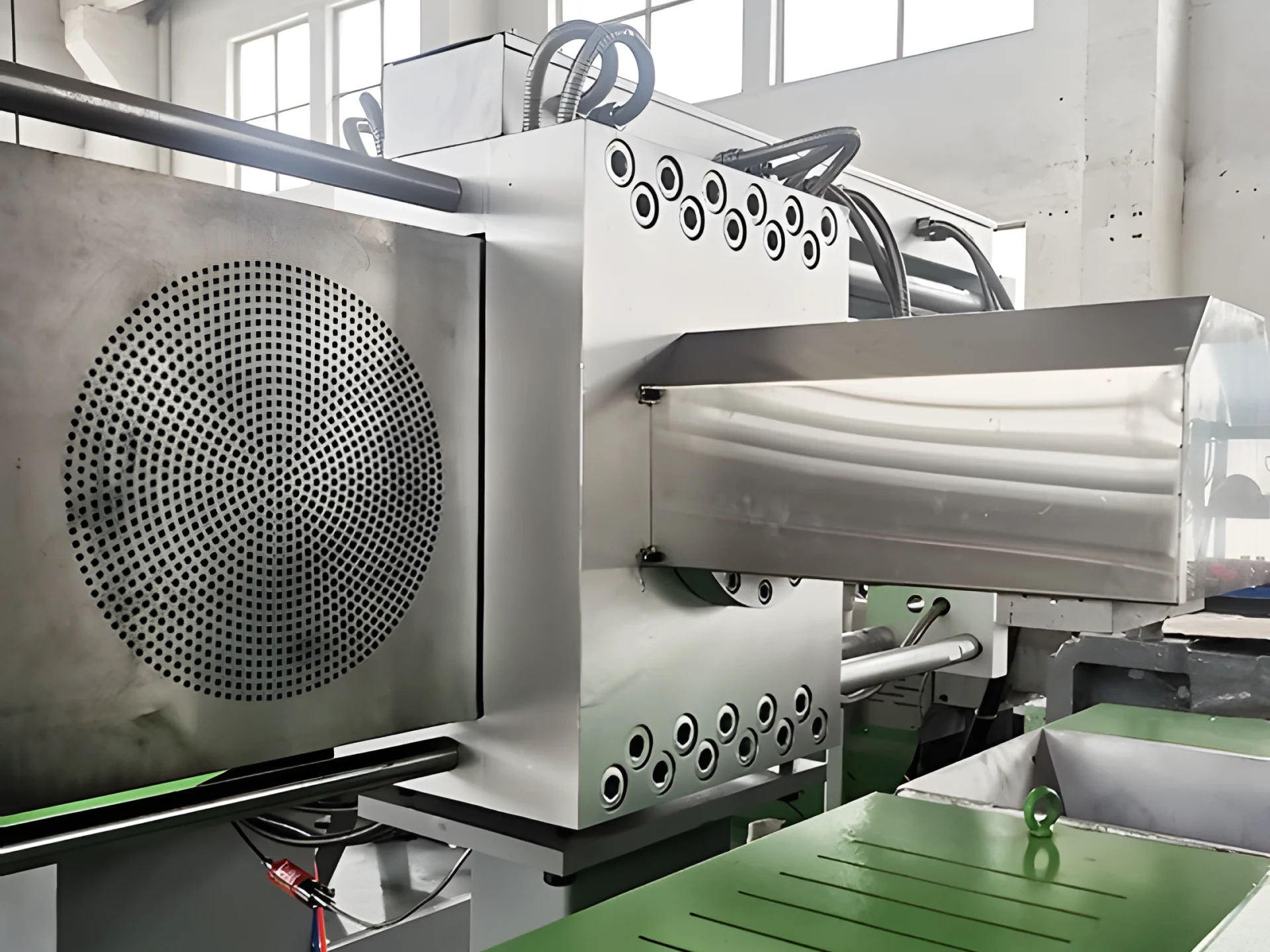

Filtrasi Lelehan Berkelanjutan

Pengubah layar otomatis menghilangkan kontaminan tanpa mengganggu produksi, memastikan aliran lelehan murni.

-

Pengeringan yang Efisien

Pengering sentrifugal vertikal dengan cepat menghilangkan air permukaan dari pelet, mempersiapkannya untuk klasifikasi dan penyimpanan.

-

Klasifikasi Pelet

Saringan getar mengklasifikasikan pelet berdasarkan ukuran, menghilangkan partikel yang terlalu besar atau terlalu kecil untuk menghasilkan produk akhir yang sangat seragam.

-

Ekstruder Sekrup Kembar Presisi

Memberikan pencampuran dan penyebaran yang sangat baik untuk aplikasi peracikan, memastikan homogenitas aditif dan pengisi.

Dapatkan Kualitas Pelet Premium

Sistem kami menghasilkan pelet yang bersih, seragam, dan sangat laku di pasaran dari berbagai macam bahan masukan.

Pelet PE

Pelet Film Plastik

Pelet PVC & Plastik Keras

Siap Memproduksi Pelet Plastik Premium?

Hubungi pakar kami untuk mendiskusikan material dan aplikasi spesifik Anda. Kami akan merancang lini pelet atau peracikan khusus untuk memenuhi target kualitas dan hasil produksi Anda.

Dapatkan Penawaran Sistem Kustom