In the world of plastics manufacturing, efficiency is paramount. Every gram of raw material counts, and every moment of downtime impacts the bottom line. Yet, a significant and often overlooked source of loss stems from a routine process: extruder purging. The resulting extruder head waste—large, dense lumps of solidified polymer—is frequently viewed as a costly nuisance destined for the landfill.

However, for forward-thinking manufacturers in the USA and Europe, this “waste” represents a substantial opportunity. With the right strategy and technology, plastic purge material can be transformed from a financial drain into a valuable, reusable resource. This comprehensive guide will walk you through the entire process, demonstrating how to establish a profitable in-house recycling stream. We will highlight the critical role of specialised machinery and explain why a purpose-built Extruder Head Waste Shredder from a trusted partner like Mesin Rumtoo is the cornerstone of any successful operation.

Understanding the Challenge: What is Extruder Head Waste?

Extruder head waste, also known as purge or purgings, is the plastic material removed from an extruder barrel, screw, and die. This is a necessary step during:

- Material or Colour Changes: To prevent cross-contamination.

- Scheduled Shutdowns: To clear the machine before it cools.

- Start-up Procedures: To purge any degraded material.

This material solidifies into large, irregular, and often extremely hard blocks or lumps. Its characteristics present a unique recycling challenge:

- High Density and Toughness: Purge lumps can be incredibly tough, resisting conventional size-reduction methods.

- Irregular Shapes and Sizes: Their non-uniform nature makes them difficult to handle and feed into standard machinery.

- Abrasive Properties: Some polymers, especially those with fillers like glass fibre, can be highly abrasive, causing rapid wear on equipment.

Disposing of this material is not only environmentally irresponsible but also financially draining due to landfill taxes and haulage fees. More importantly, it is a waste of high-quality polymer that could be reintroduced into your production cycle.

The Complete Recycling Workflow: A Step-by-Step Analysis

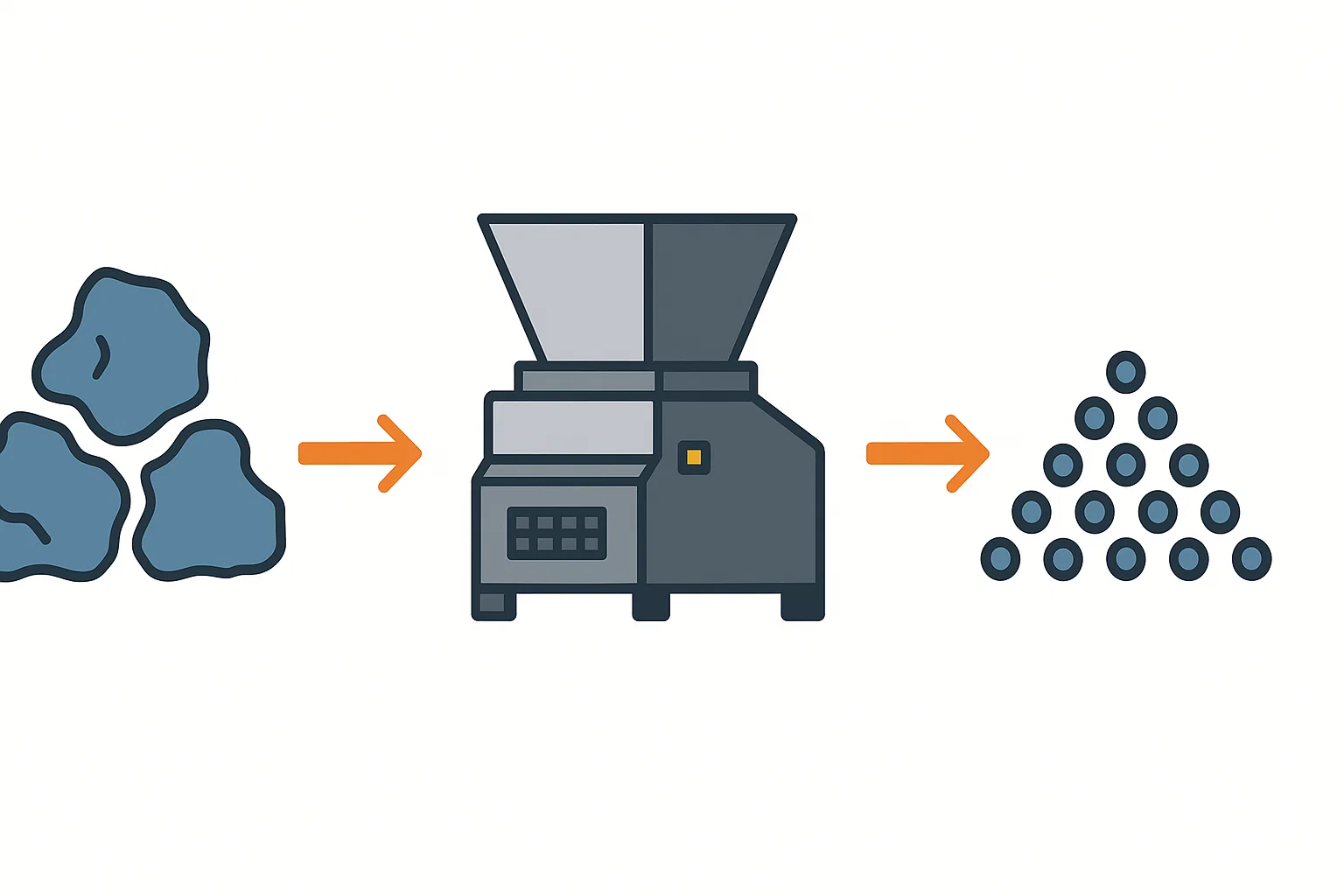

Transforming a solid purge lump into high-grade reusable pellets requires a multi-stage process. While each step is important, the initial size reduction is the most critical and challenging phase.

Step 1: Collection and Segregation

The foundation of high-quality recycling begins at the source.

- Clean Collection: Ensure purge lumps are collected in clean, designated bins to avoid contamination from floor sweepings, oils, or other debris.

- Material Segregation: If you work with multiple polymers (e.g., HDPE, PP, PC, PET), it is vital to keep purgings segregated. Mixing different plastic types will drastically reduce the value and usability of the final recyclate. Proper labelling and dedicated storage areas are essential.

Step 2: Primary Size Reduction – The Make-or-Break Stage

This is where most recycling initiatives either succeed or fail. The sheer bulk and toughness of extruder purgings mean they cannot be processed by just any machine.

Why a Standard Granulator Fails

It is a common misconception that a granulator can handle purge lumps. Attempting to do so is inefficient and often destructive. Here’s why:

- High-Speed, Low-Torque Design: Granulators use high-speed, scissor-action knives to cut small, uniform-sized plastic parts. They lack the immense torque required to break down a large, solid mass.

- Risk of Catastrophic Failure: Feeding a large purge lump into a granulator will likely cause the rotor to jam and stall. The shock load can lead to cracked rotors, chipped or broken blades, and motor burnout, resulting in costly repairs and extensive downtime.

- Feeding Chamber Limitations: The infeed opening and cutting chamber of a granulator are simply not designed to accommodate bulky, irregular lumps.

The Essential Solution: The Extruder Head Waste Shredder

To effectively process purge material, you need a machine engineered for the task: a heavy-duty, single-shaft shredder.

A single-shaft shredder operates on a principle of high torque and low speed. This allows it to methodically break down the toughest materials without stalling. The process works as follows:

- Loading: The large purge lump is dropped into the shredder’s spacious hopper.

- Hydraulic Pusher (Ram): A powerful hydraulic ram automatically pushes the material horizontally into the cutting rotor. This controlled feeding prevents overloading and ensures constant, efficient shredding.

- High-Torque Cutting: The slow-rotating, hardened-steel rotor is equipped with robust, square cutter knives. As the rotor turns, these knives grab the purge lump, biting off and tearing away smaller, more manageable pieces.

- Screen Sizing: The shredded material falls through a heavy-duty screen located beneath the rotor. The size of the holes in this screen dictates the final output size of the plastic flakes (typically 30-50mm).

For this critical first step of coarse shredding and size reduction, an extruder head waste shredder is the indispensable foundation of the entire recycling line. A reliable machine, such as those engineered by Mesin Rumtoo, ensures that the most difficult part of the process is handled safely and efficiently, paving the way for the subsequent stages.

Rumtoo Machine: Extruder Head Waste Recycling Workflow

Step 3: Conveying

Once shredded into uniform flakes, the material is far easier to handle. An automated conveying system, such as a belt or screw conveyor, efficiently transports the flakes from the shredder’s discharge point to the next stage of the process, minimising manual labour and maintaining a continuous workflow.

Step 4: Washing and Drying (Optional but Recommended)

For applications requiring the highest purity, a washing and drying stage can be incorporated.

- Friction Washers: Use high speeds to scrub the flakes, removing any surface dirt or minor contaminants.

- Float-Sink Tanks: Can separate different plastic types by density or remove heavy contaminants.

- Pengeringan: A mechanical or thermal dryer removes moisture to prepare the flakes for extrusion.

While not always necessary for clean, well-segregated in-house purges, this step is crucial if the material has any level of contamination.

Step 5: Repelletizing

This is the final stage of transformation. The clean, dry, and uniformly sized plastic flakes are fed into a pelletizing extruder. Inside, the material is melted, homogenised, filtered to remove any final impurities, and extruded through a die into spaghetti-like strands. These strands are immediately cooled in a water bath and then cut by a pelletizer into uniform, cylindrical pellets.

The result? High-grade recycled pellets with properties closely matching those of virgin material, ready to be reintroduced into your production lines.

The Business Case: ROI and Sustainability

Investing in a robust recycling system, spearheaded by an Extruder Head Waste Shredder, delivers a powerful return on investment.

| Benefit Category | Detailed Advantage |

| Direct Cost Savings | Drastically reduce or eliminate landfill disposal fees. Significantly lower your procurement costs by substituting expensive virgin resin with your own high-quality recycled pellets. |

| New Revenue Streams | If your recycled material exceeds your internal needs, you can sell the high-demand pellets on the open market, creating a new profit centre for your business. |

| Enhanced Sustainability | Meet and exceed corporate sustainability goals (ESG) and evolving environmental regulations in the USA and Europe. Showcase your commitment to the circular economy, enhancing your brand’s reputation. |

| Operational Control | Gain full control over a portion of your raw material supply chain. You are no longer solely dependent on virgin resin price volatility and can ensure consistent quality in your recycled feedstock. |

The expertise of Mesin Rumtoo lies in understanding these benefits and engineering systems that maximise them. We don’t just sell equipment; we provide comprehensive solutions tailored to your specific polymer types, throughput requirements, and facility layout.

Why Partner with Rumtoo Machine?

In an industry where reliability is non-negotiable, Mesin Rumtoo stands out for its commitment to Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

- Expertise: We specialise in heavy-duty recycling machinery. Our engineers understand the unique stresses that purge lumps place on a shredder and design our systems with oversized gearboxes, robust rotor configurations, and advanced wear-resistant components to ensure longevity and performance.

- Customisation: We know that no two manufacturing plants are the same. Whether you process flexible PP or rock-hard, glass-filled PC, we can configure an Extruder Head Waste Shredder with the right motor power, cutter geometry, and screen size for your exact needs.

- Trustworthiness: A Mesin Rumtoo shredder is an investment in uptime. Our machines are built for durability and ease of maintenance, with accessible components and world-class after-sales support to keep your operations running smoothly.

Pertanyaan yang Sering Diajukan (FAQ)

1. What is the main difference between a shredder and a granulator for purge material?

A shredder is a high-torque, low-speed machine designed to break down large, tough, and irregular materials like purge lumps into smaller, coarse flakes. A granulator is a high-speed, low-torque machine designed to process small, pre-shredded, or thin-walled parts into fine regrind. A shredder is essential for the initial size reduction of purge; a granulator is not suitable for this task.

2. Can a single Rumtoo Machine shredder handle different types of plastic purges (e.g., HDPE, PP, PC)?

Yes. Our shredders are highly versatile. While a machine can be optimised for a specific polymer, it can effectively process a wide range of thermoplastics. For customers processing very different materials (e.g., soft, flexible PE vs. hard, brittle PC), we can recommend specific rotor and blade configurations, and even programme settings, to ensure optimal performance for each.

3. What is the typical return on investment (ROI) for an extruder head waste shredder system?

The ROI is typically very rapid, often within 12-24 months. It is calculated based on three key factors: the cost of landfill disposal you eliminate, the value of the virgin resin you no longer need to purchase, and any potential revenue from selling excess recycled pellets. Our team at Mesin Rumtoo can help you perform a detailed cost-benefit analysis based on your specific operational data.

4. What kind of maintenance is required for a Rumtoo Machine shredder?

Our shredders are designed for reliability and ease of maintenance. Routine maintenance includes regular greasing of bearings, checking hydraulic fluid levels, and periodically rotating or replacing the cutter knives. The knives are four-sided, meaning they can be rotated three times before needing to be replaced, significantly extending their life. The screen is also easily replaceable. We provide comprehensive manuals and support to make maintenance straightforward.

Conclusion: Turn Your Waste into a Competitive Advantage

Extruder head waste is an unavoidable by-product of plastics manufacturing, but it doesn’t have to be a liability. By viewing it as a valuable raw material in waiting, you can unlock significant financial and environmental benefits.

The journey begins with the right technology. A powerful, reliable, and purpose-built Extruder Head Waste Shredder is the non-negotiable first step to transforming tough plastic lumps into a profitable resource.

Ready to convert your plastic waste into a profit centre?

Contact the experts at Mesin Rumtoo today. Our team is standing by to analyse your specific requirements and engineer a bespoke recycling solution that integrates seamlessly into your operations.

Request a free, no-obligation quote now and take the first step towards a more profitable and sustainable future.