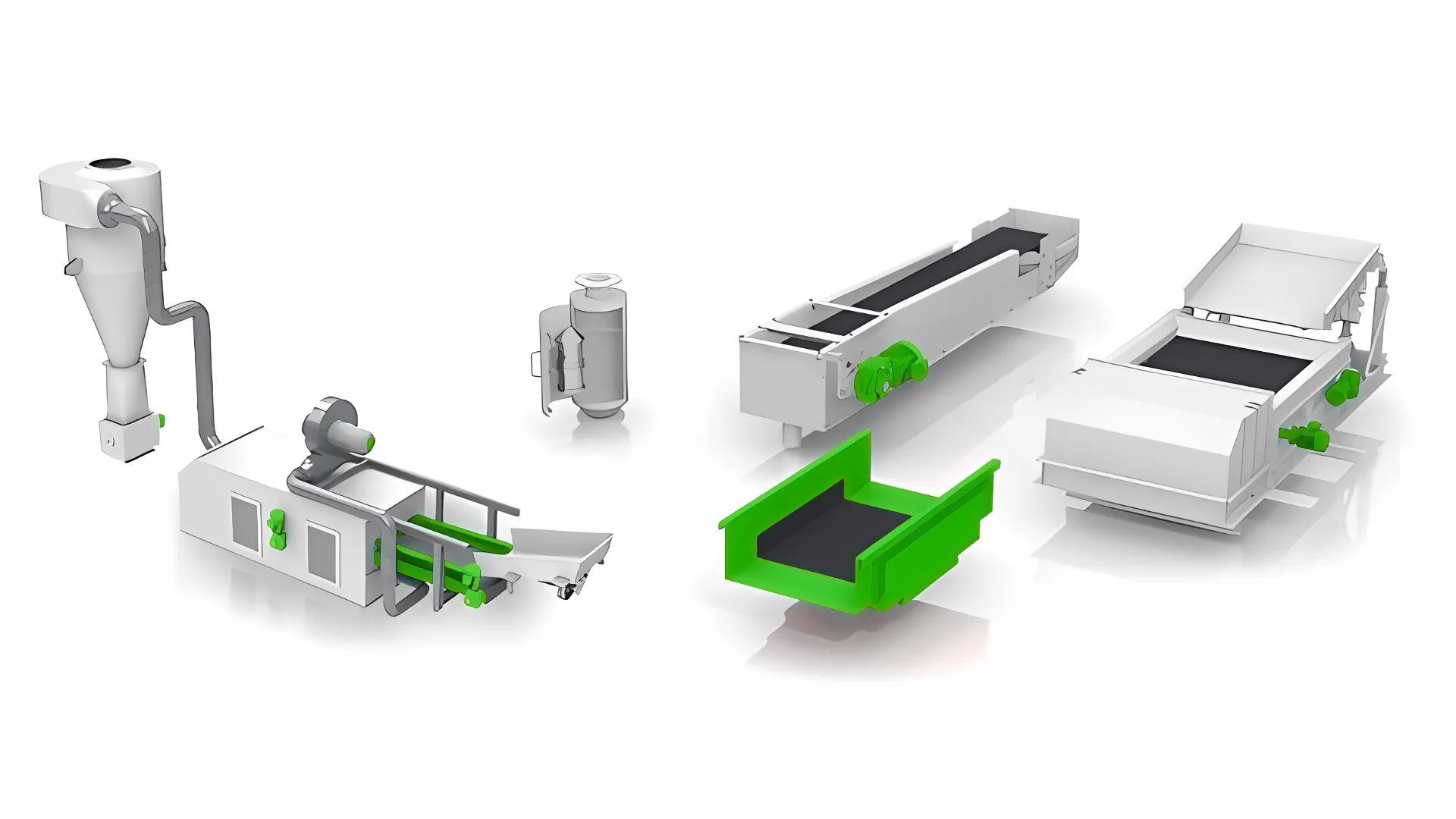

Separator Equipment Overview

Separator equipment is essential in various industries, particularly in recycling and waste management, where it plays a vital role in sorting and separating materials based on their physical properties such as density, magnetism, and particle size. This equipment is designed to improve the efficiency and effectiveness of processing operations, ensuring that different materials are correctly sorted for further processing or disposal.

Types of Separator Equipment:

- Magnetic Separators:

- Used to remove ferrous metals from waste streams.

- Ideal for recycling facilities to separate iron and steel from other materials.

- Eddy Current Separators:

- Used for separating non-ferrous metals like aluminum and copper from other waste materials.

- Works by inducing an electrical current that repels the metals from the waste stream.

- Separates materials based on density using airflow.

- Commonly used to sort lighter materials like plastic from heavier ones like glass or metal.

- Sink/Float Separation Tanks:

- Specifically designed for plastic recycling.

- Operates by immersing materials in water, where heavier contaminants sink and lighter plastics float for easy separation.

- Essential in the recycling of plastic bottles, these machines remove labels and glue, ensuring the purity of the recycled material.

- Debalers:

- Used to break down bales of recyclable materials, preparing them for further processing.

Applications and Benefits:

- Recycling Industry: Separator equipment is crucial for processing PET bottles, electronic waste, and other recyclable materials. It ensures that materials are cleanly separated for efficient recycling.

- Waste Management: In municipal and industrial waste streams, separators help in the recovery of valuable materials, reducing landfill waste and supporting environmental sustainability.

- Material Recovery: These machines allow for the recovery of materials that can be reused, reducing the need for virgin resources and minimizing environmental impact.

Customization and Integration:

Modern separator equipment can be customized to meet the specific needs of different industries. These systems are often integrated with other processing equipment to create a seamless operation that maximizes efficiency and output. Automated controls and real-time monitoring are common features that help reduce labor costs and improve accuracy in separation processes.