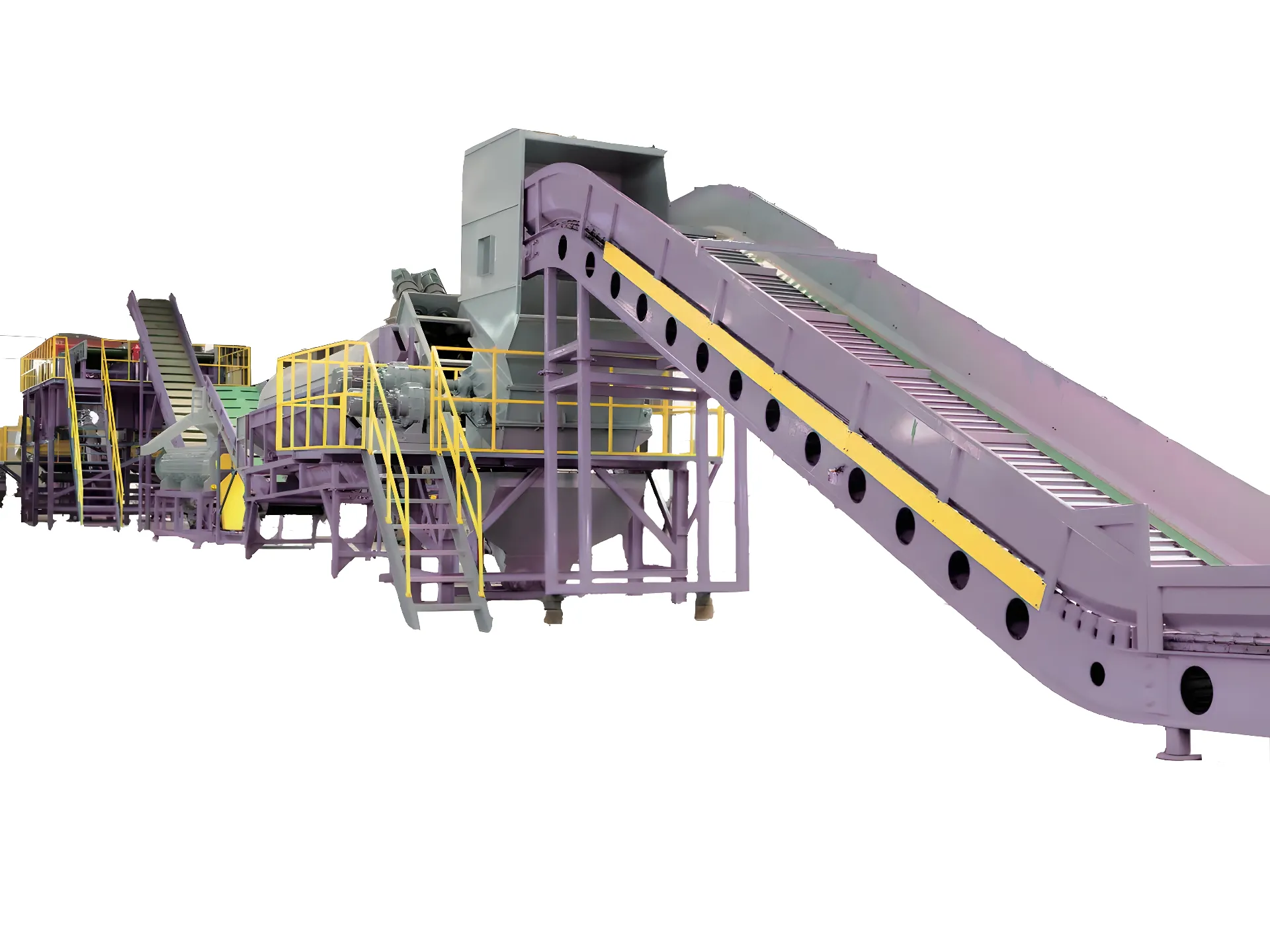

Advanced PET Bottle Washing & Recycling Line

Transforming post-consumer PET bottles into high-purity, food-grade rPET flakes. Drive profitability through sustainable manufacturing.

Superior Purity

Achieve final flake purity up to 99.8%, with PVC, moisture, and contamination levels far below industry standards (e.g., <100 ppm).

Operationel effektivitet

Optimized water treatment and energy-saving systems reduce consumption, significantly lowering your operational expenditure (OPEX).

Robust konstruktion

Utilizes high-grade, corrosion-resistant materials (e.g., SUS304) and world-class components for maximum uptime and equipment longevity.

Turnkey Solutions

From initial layout design and manufacturing to installation, commissioning, and staff training, we provide comprehensive project management.

Our Standard Process Flow

Core Components & Specifications

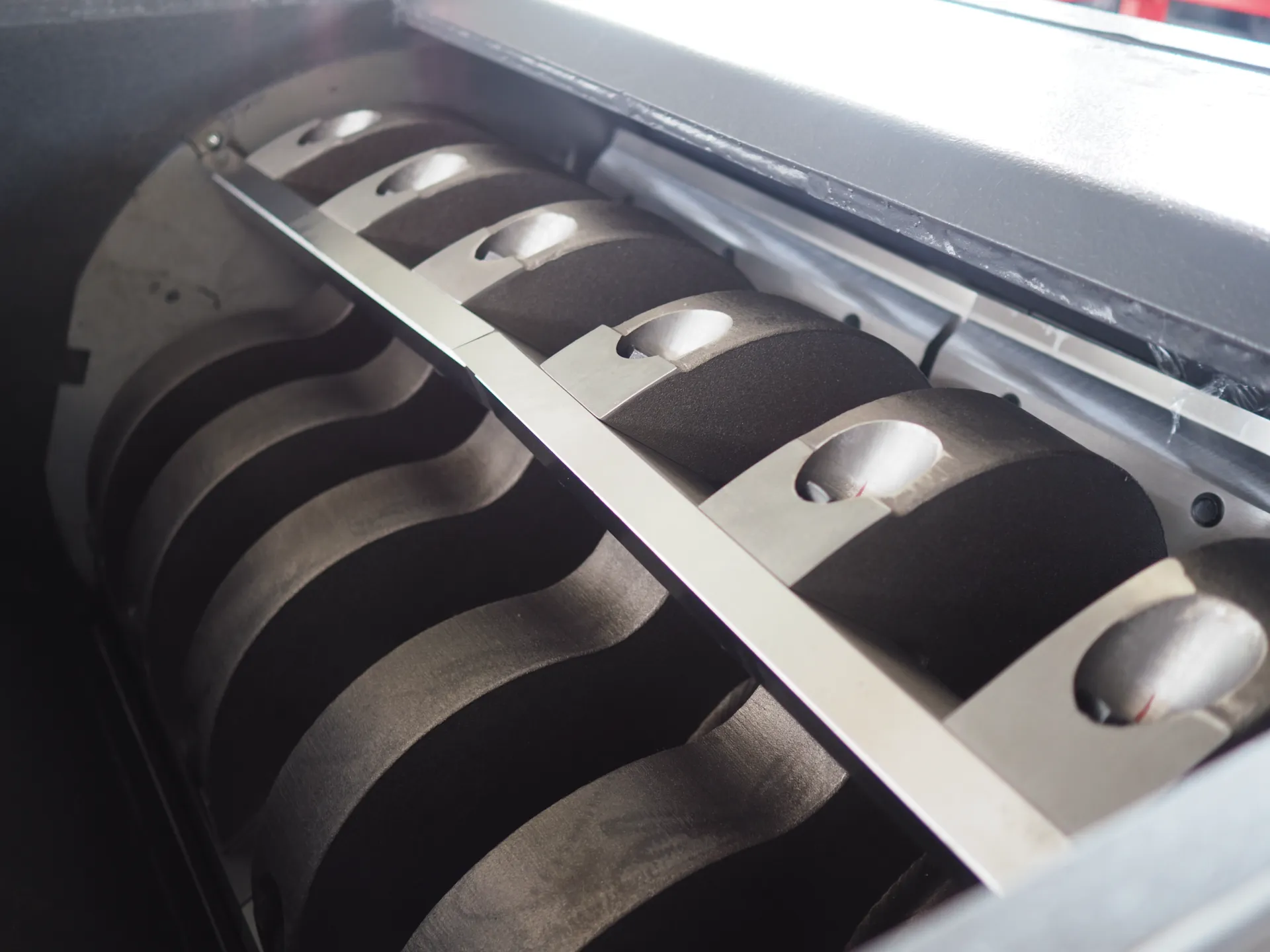

Heavy-Duty Granulator

Features a staggered, dual-scissor cutting action for high throughput and uniform flake size. Blades are crafted from D2 high-carbon steel for extended service life and can be easily sharpened and recalibrated.

Steam Hot Washer System

Effectively removes tenacious contaminants like glue, oil, and organic residues. Incorporates a PLC-controlled chemical dosing and temperature regulation system to ensure consistent and optimal washing performance.

| Technical Parameter | Model: RTMPL-500 | Model: RTMPL-1000 | Model: RTMPL-2000 |

|---|---|---|---|

| Kapacitet | 500 kg/t | 1,000 kg/hr | 2,000 kg/hr |

| Installed Power | Approx. 150 kW | Approx. 280 kW | Approx. 450 kW |

| Vandforbrug | 1-1.5 m³/Tonne | 1-1.2 m³/Tonne | 0.8-1 m³/Tonne |

| Final Moisture | < 1% | ||

Final Product & Applications

High-Purity rPET Flakes

.webp)

Polyester Staple Fiber (PSF)

PET Strapping Bands

Request a Customized Quotation

Provide your project details below. Our engineering team will analyze your requirements and contact you within one business day with a tailored proposal.

Ofte stillede spørgsmål

What is the typical ROI for a PET washing plant?

The Return on Investment (ROI) depends on factors like local raw material cost, electricity rates, labor costs, and the market price for rPET flakes. However, our high-efficiency lines are designed to maximize profitability, and we can provide a detailed ROI analysis based on your specific operational context.

Do you offer post-installation support and spare parts?

Absolutely. We provide a comprehensive warranty, ongoing technical support, and a full inventory of critical spare parts to ensure minimal downtime and smooth, continuous operation of your plant.

How is the system customized for different types of input material?

Our system is modular. Based on the contamination level of your input bales (e.g., high sand, oil, or label content), we can add or enhance specific modules like pre-washers, dual label separators, or advanced sorting systems to guarantee the required output quality.