Transform Plastic Waste into Valuable Resources

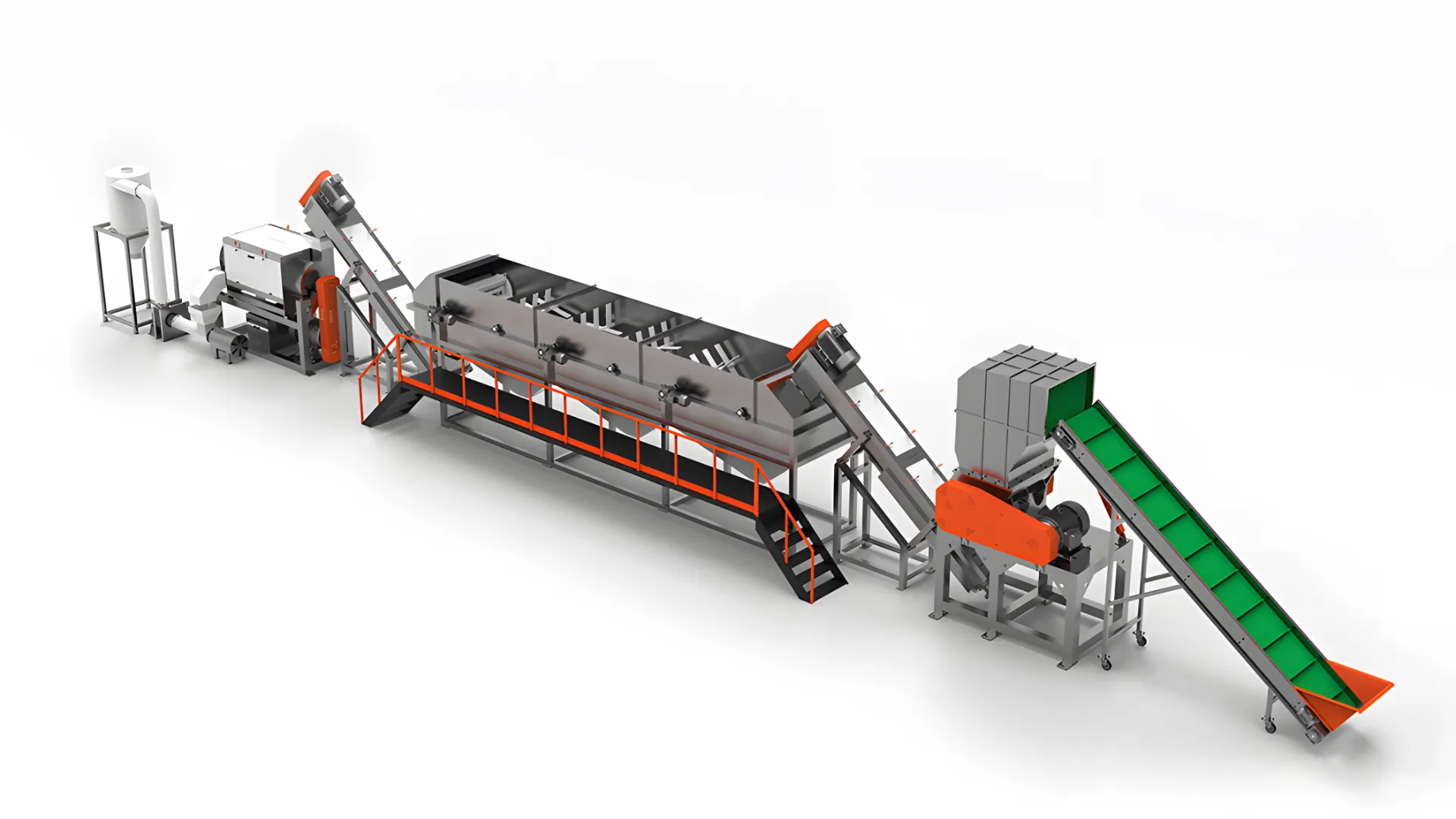

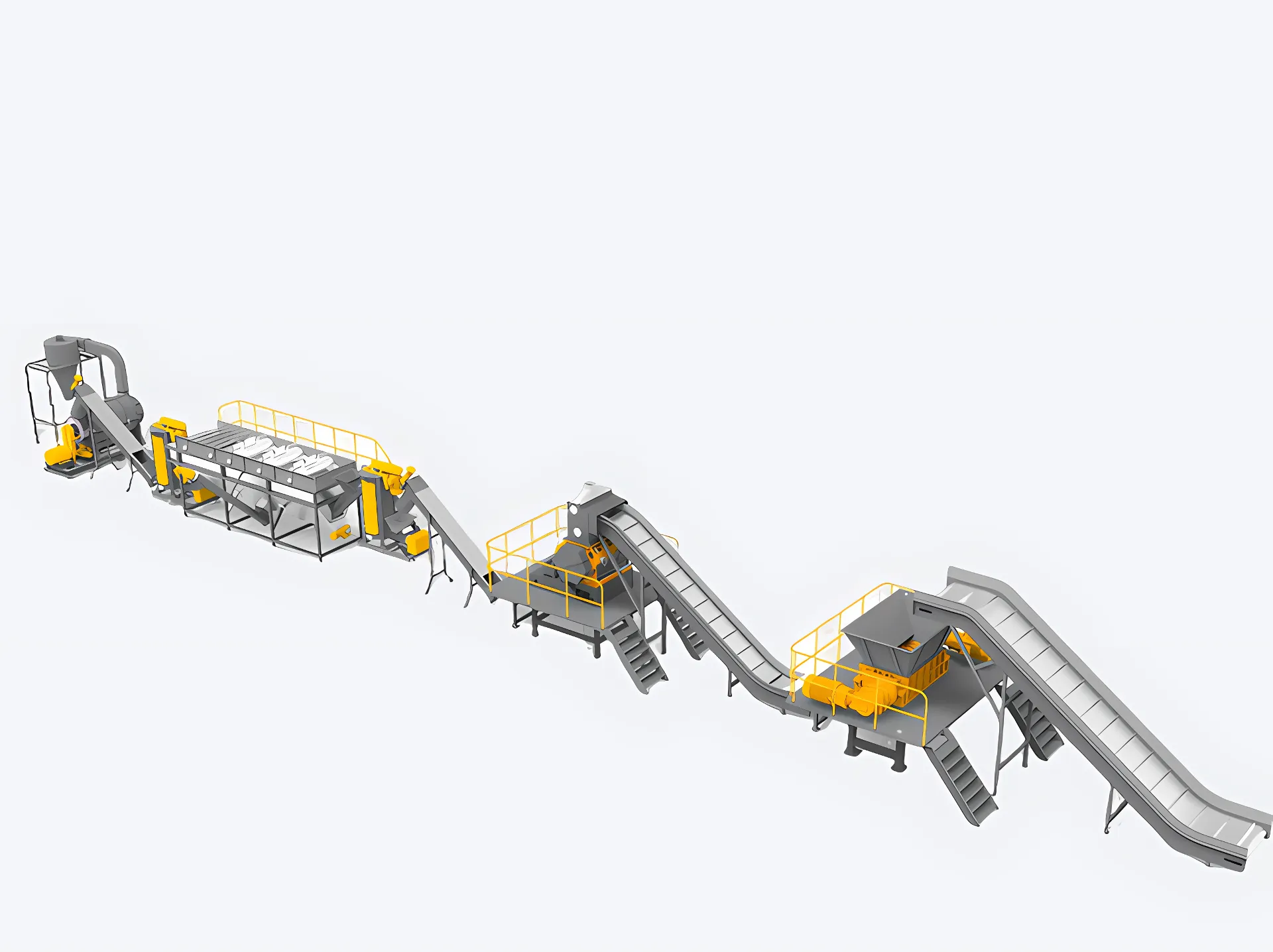

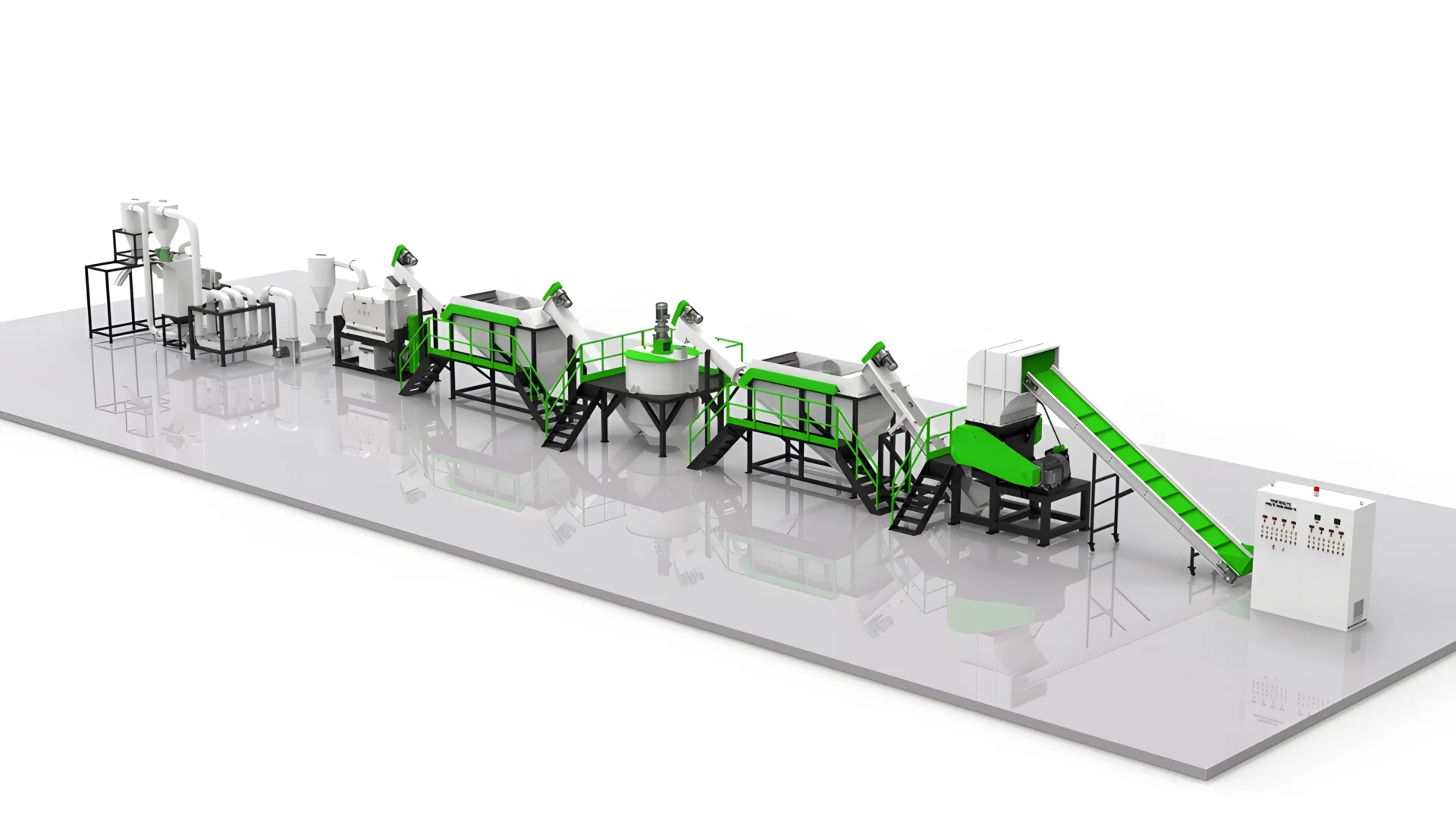

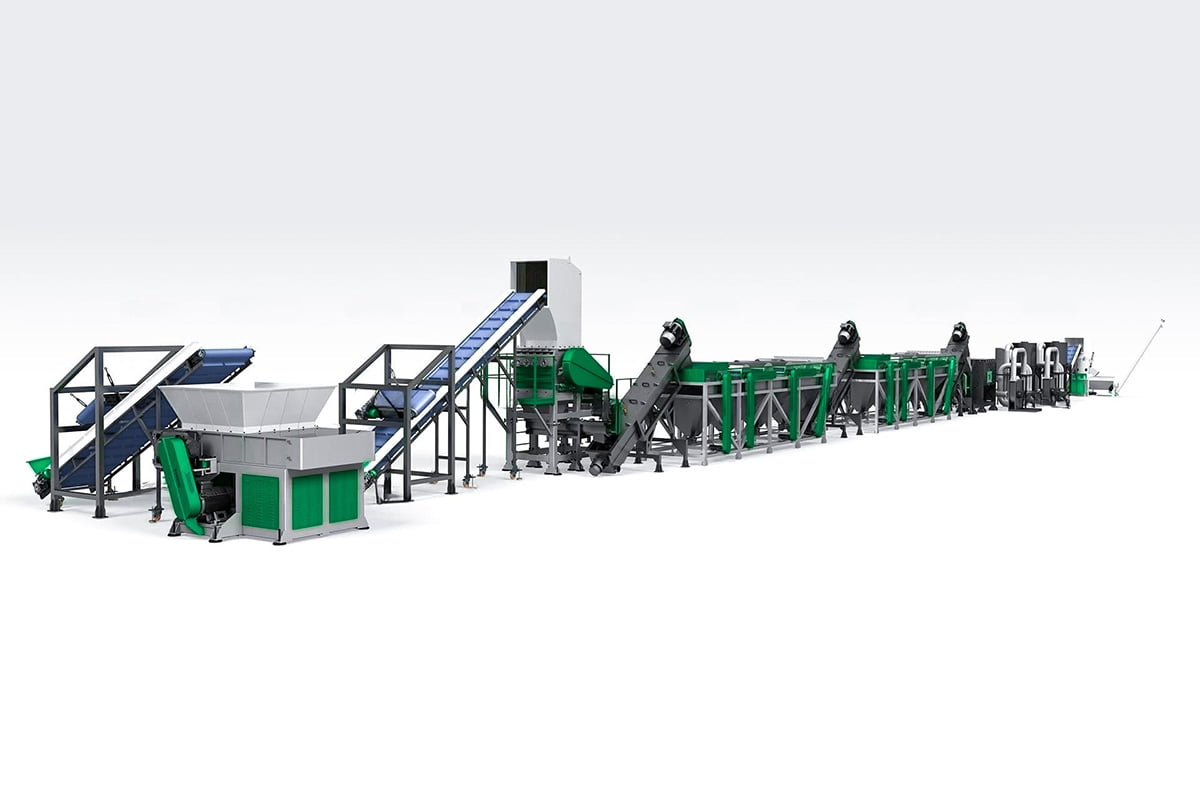

Our advanced plastic film washing and recycling line efficiently processes post-consumer and industrial waste, delivering high-purity, reusable materials ready for the circular economy.

Request a Customised ProposalWhy Choose Our System?

Our technology is engineered for superior performance, efficiency, and reliability, ensuring you get the highest return on your investment.

High Purity Output

Achieve final product moisture levels below 3% with exceptional cleanliness, perfect for high-grade pelletising.

Ekologický provoz

Designed for reduced water and energy consumption, minimising your operational footprint and costs.

Robust & Versatile

Effectively processes a wide range of materials, from agricultural films to post-consumer woven bags.

Automated Process

Integrated control systems ensure seamless operation, reducing labour requirements and human error.

From Waste to Worth: A Step-by-Step Process

Engineered for Peak Performance

Explore the key components that make our recycling line a leader in the industry.

Jednohřídelový drtič

The first step in size reduction, our robust shredder efficiently processes baled or loose plastic films and bags, ensuring a consistent particle size for optimal washing.

- High-Torque Rotor: Powers through tough materials with minimal energy consumption.

- Durable Blades: Made from high-strength D2 alloy steel for extended life and performance.

- Hydraulic Pusher: Ensures continuous material feed to the rotor for maximum throughput.

Hot Washer System

Crucial for removing oils, glues, and stubborn organic contaminants. Our system uses heated water and optimised chemical agents to achieve a deep clean, significantly improving the quality of the final product.

- Integrated Heating: Eliminates the need for an external steam boiler, simplifying installation and operation.

- High-Speed Agitation: Ensures all flake surfaces are exposed to the cleaning solution.

- Automated Dosing: Precisely controls chemical additives for consistent and efficient cleaning.

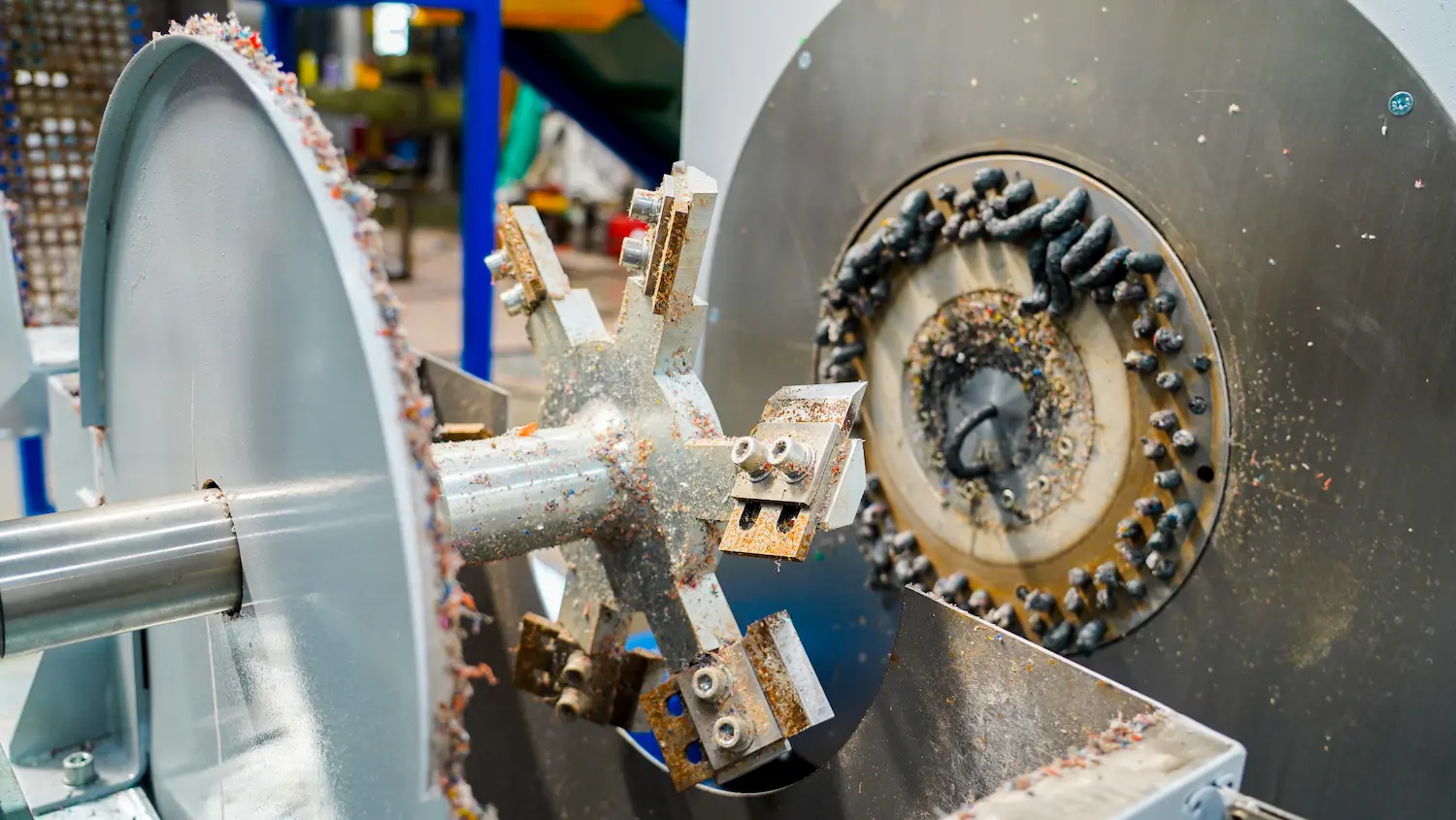

Film Squeezer & Dryer

A critical innovation that replaces traditional centrifugal and thermal dryers for film. This machine squeezes water out and uses frictional heat to semi-plasticise the material, resulting in dense, dry agglomerates with moisture below 2%.

- Superior Dewatering: Drastically reduces moisture, making it ideal for direct feeding into a pelletiser.

- Increases Bulk Density: Compacts fluffy film into dense particles, improving extruder feeding efficiency.

- Energeticky účinný: Consumes significantly less energy compared to a combined dewatering and thermal drying setup.

Technical Specifications Overview

| Parametr | Standard Configuration | Notes |

|---|---|---|

| Throughput Capacity | 300 - 2000 kg/hour | Customisable based on material and requirements. |

| Použitelné materiály | PE/PP Film, Woven Bags, Non-Woven, Artificial Grass | Testing available for other materials. |

| Final Moisture Content | < 3% (with Film Squeezer) | Optimal for direct feed to pelletising extruder. |

| Total Power Installed | Varies (e.g., ~250 kW for 500 kg/h line) | Line-specific; detailed in official quotation. |

| Kontrolní systém | Centralised PLC with Touchscreen HMI | Siemens or equivalent components. |

See Our System in Action

From dirty agricultural film to clean, valuable pellets. Witness the transformation and explore the wide range of materials our line can handle.

Processable Materials

Get Your Customised Solution & Quotation

Our team is ready to help you configure the perfect recycling line for your specific materials and output goals. Fill out the form below, and one of our specialists will be in touch shortly.

Často kladené otázky

Find quick answers to common questions about our plastic film recycling line.