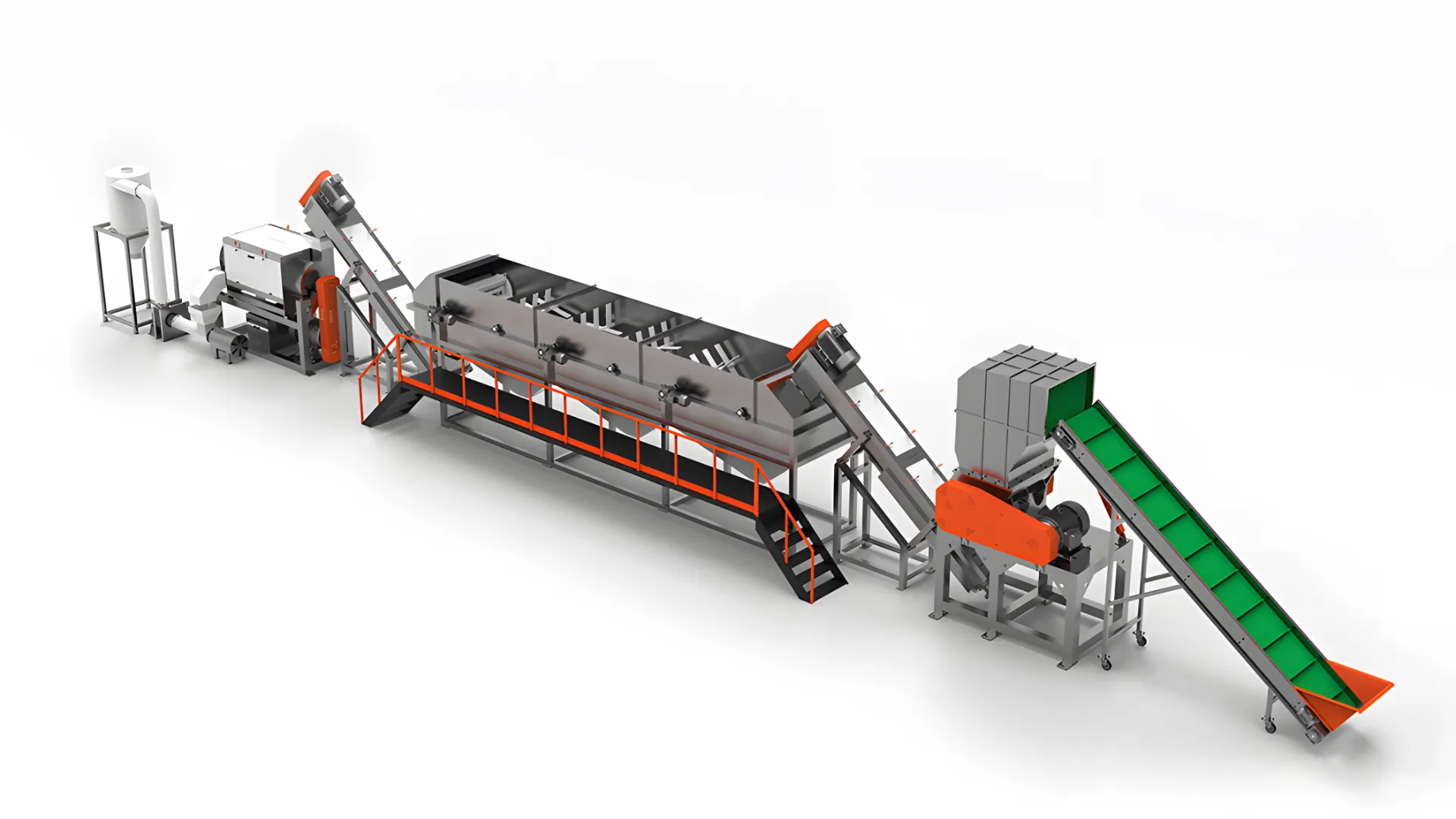

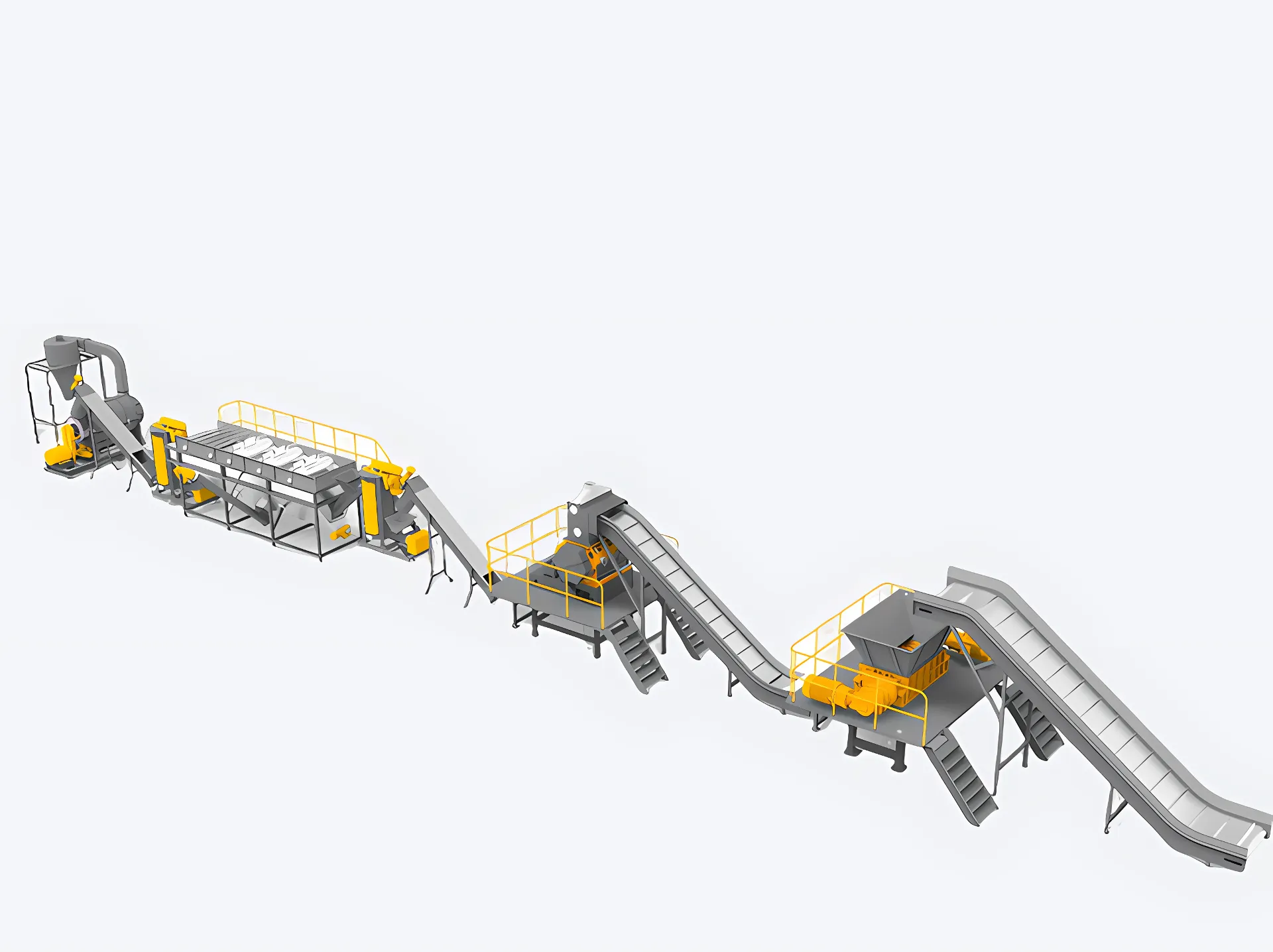

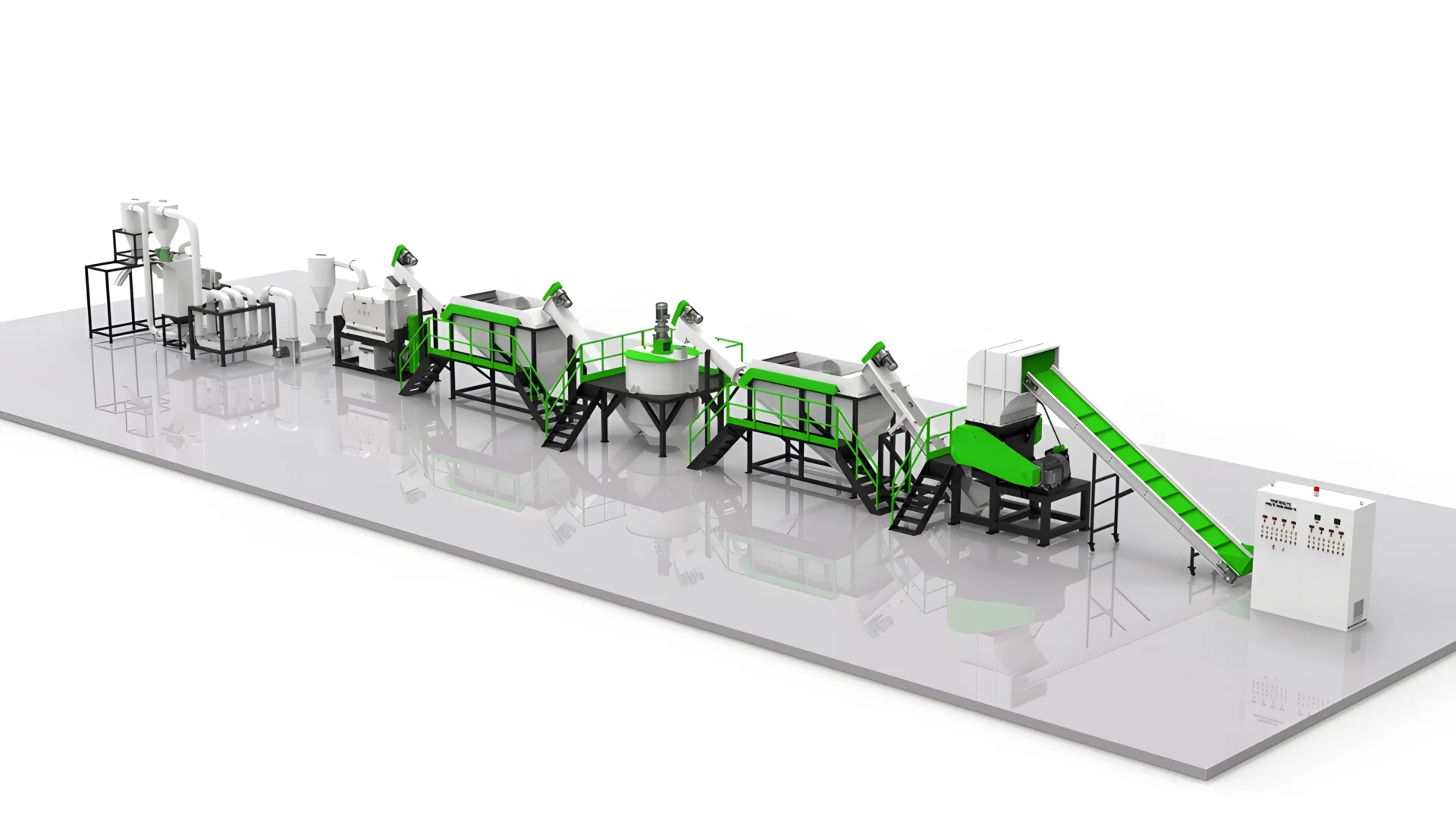

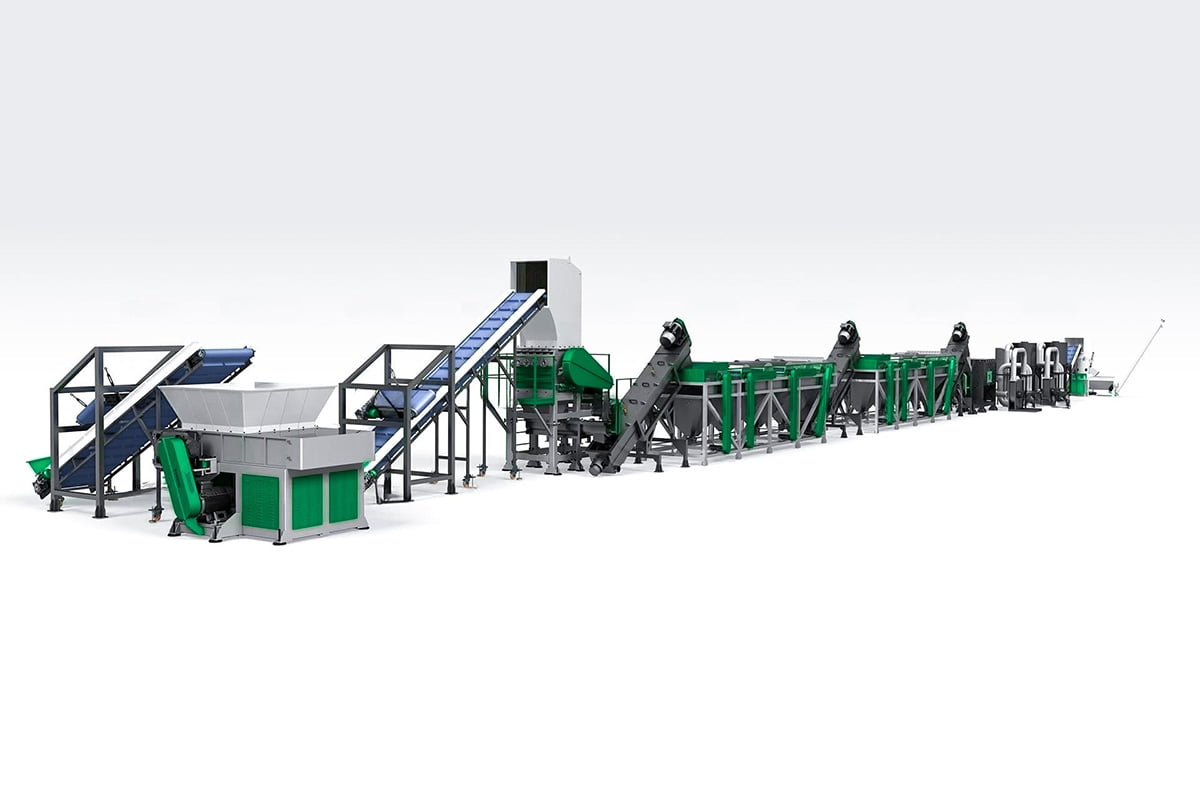

Advanced Plastic Washing Line

Transforming plastic waste into high-value, reusable raw materials with unmatched efficiency and sustainability.

Request a Custom QuoteWhy Choose Our Washing Lines?

Our technology is engineered to deliver superior performance, reliability, and profitability for your recycling operations.

High Efficiency

Process up to 1000 kg/hr with minimal water and energy consumption.

Eco-Friendly

Advanced water circulation system reduces wastewater by up to 90%.

Durable & Reliable

Built with high-wear-resistant materials for 24/7 operation and long service life.

Superior Purity

Effectively removes contaminants for premium quality flakes with <1% moisture.

Our 4-Step Washing Process

A fully automated system designed for maximum cleaning and separation efficiency, turning waste into value.

1. Shredding

Waste is shredded into uniform flakes for effective washing.

2. Washing & Floating

High-speed friction washers and float-sink tanks separate plastics from heavy contaminants.

3. Dewatering & Drying

Mechanical and thermal systems reduce moisture to under 1%.

4. Collection

Clean, dry flakes are collected, ready for pelletizing or direct sale.

Key Components & Parameters

Explore the core components and technical specifications that make our washing lines a market leader.

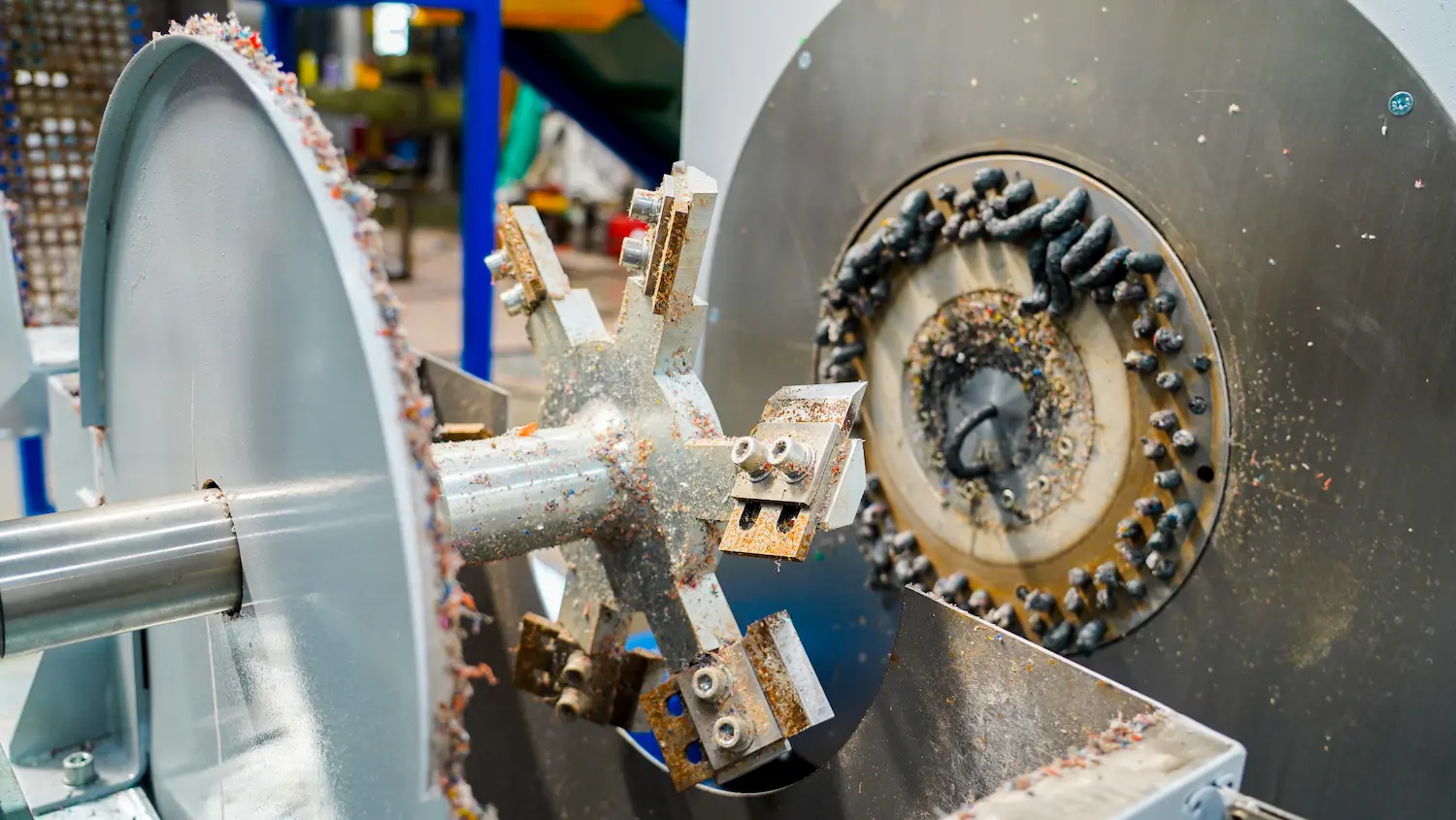

Heavy-Duty Crusher

Features specially designed V-type rotor knives for high throughput and uniform flake size. Easily handles post-consumer bottles and rigid plastics.

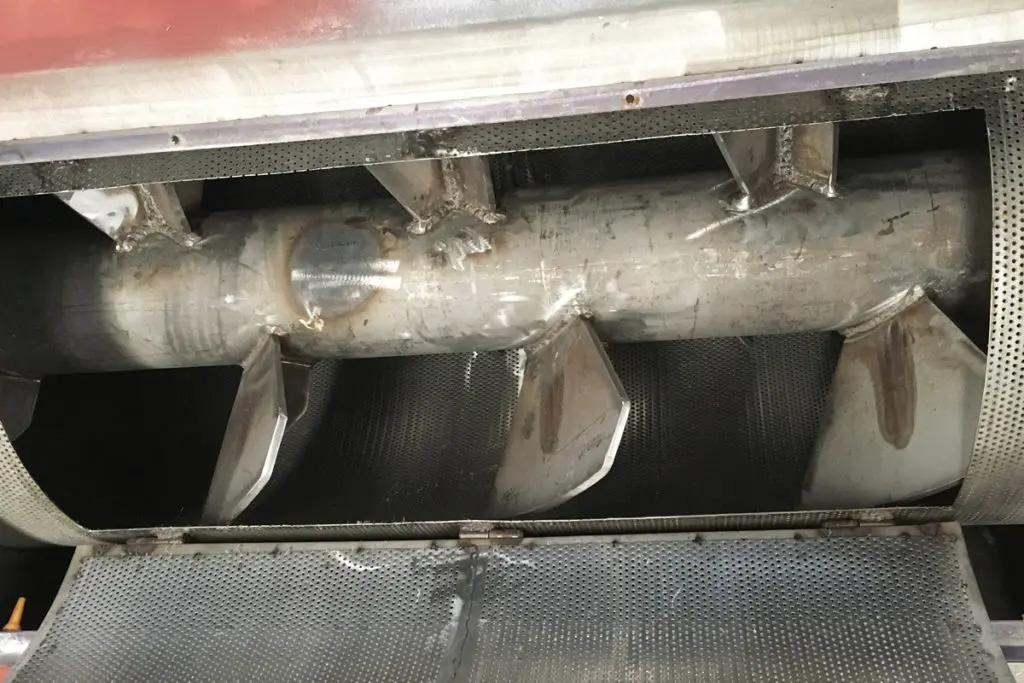

High-Speed Friction Washer

Paddles rotating at 1,200 RPM create intense friction to scrub off tough contaminants like dirt, sand, and paper labels efficiently.

Centrifugal & Thermal Dryer

A two-stage drying process ensures the final product moisture is below 1%, critical for high-quality extrusion and pelletizing processes.

Plant Parameters

| Capacity (kg/h) | Install Power (kW) | Required Area (m²) | Required Staff | Compressed Air (Mpa) | Required Water (m³/h) |

|---|---|---|---|---|---|

| 300 | 150 | 350 | 4 | 0.6 – 0.8 | 3 |

| 500 | 230 | 460 | 6 | 0.6 – 0.8 | 4 |

| 1000 | 430 | 500 | 6 | 0.6 – 0.8 | 5 |

Gallery & Live Demo

See our equipment in action and the high-quality output it produces.

Get a Custom Solution & Quote

Our engineers will help you configure the perfect washing line for your specific raw materials and output requirements.

Frequently Asked Questions

What types of plastic can this line wash?

Our standard lines are optimized for rigid plastics like PET (bottles), HDPE (containers), and PP (chairs, pipes). We also provide customized solutions for soft plastics like LDPE/LLDPE films and PP woven bags. Let us know your material, and we will build the line for you.

What is the final quality of the plastic flakes?

The final product is exceptionally clean. Moisture content is guaranteed to be less than 1%, and major contaminants like PVC, metals, and adhesives are controlled to extremely low levels (e.g., <100ppm), making the flakes suitable for direct use in high-end applications like bottle-to-bottle recycling, fiber production, or strapping.

Do you provide installation and after-sales support?

Absolutely. We offer complete turn-key solutions, including on-site installation, commissioning, and comprehensive operator training. Our after-sales support includes a 12-month warranty, remote technical assistance, and readily available spare parts to ensure minimal downtime.