لقد أولت الجهود العالمية نحو الاقتصاد الدائري أهمية غير مسبوقة لإعادة تدوير البلاستيك بكفاءة. وبصفتها شركة متخصصة في آلات إعادة تدوير البلاستيك، تُدرك شركة رومتو أهمية جودة المواد المُعاد تدويرها. ومن أهم التقنيات التي تضمن مستويات نقاء عالية في البلاستيك المُستعاد: خزان الفصل بالوعة العوامةتستكشف هذه المقالة ماهية هذه الخزانات، وكيفية عملها، ولماذا تعد ضرورية لمرافق إعادة التدوير الحديثة.

ما هو خزان الفصل بالوعة العائمة بالضبط؟

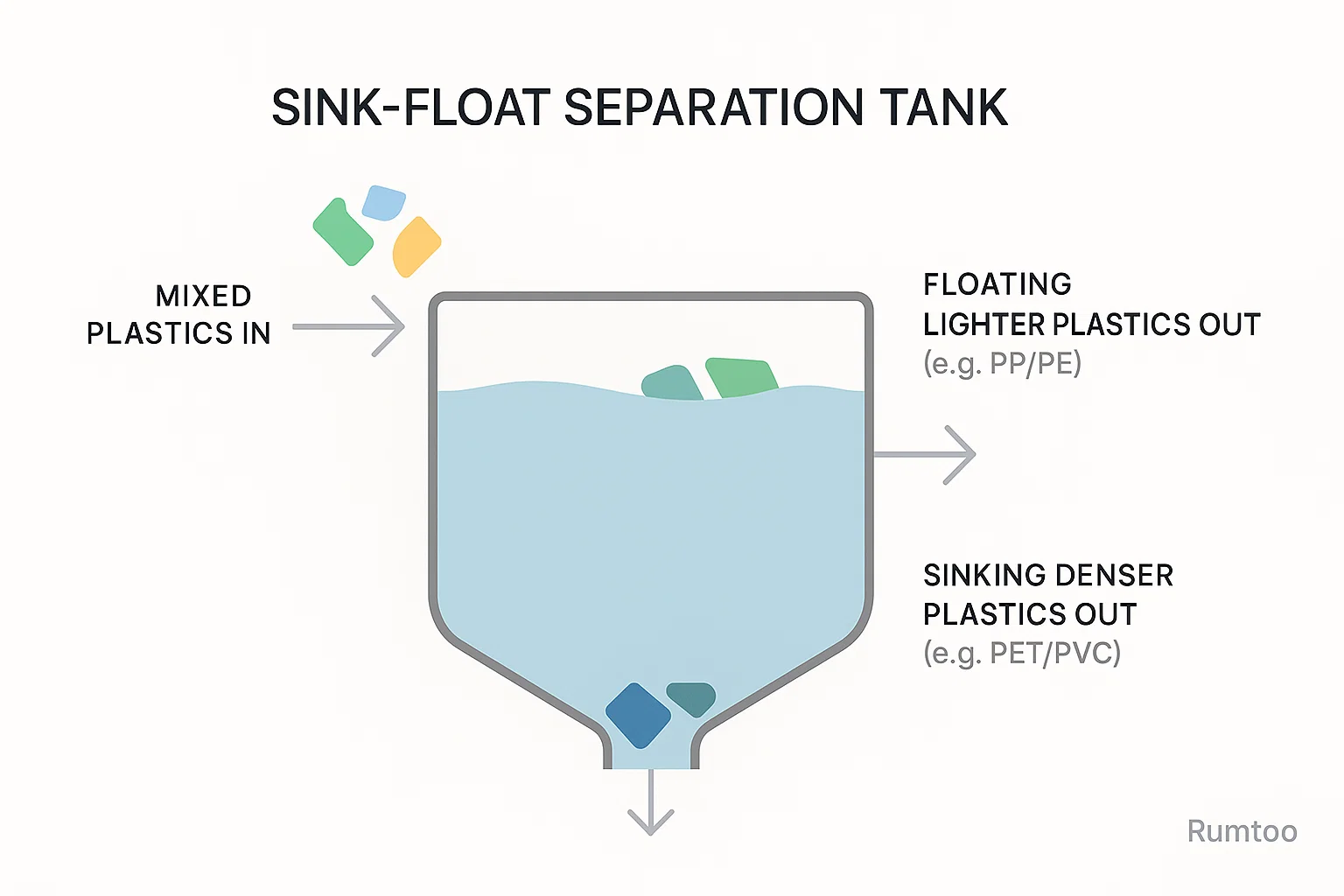

أ خزان الفصل بالوعة العوامة هي معدة صناعية مصممة لفصل أنواع مختلفة من البلاستيك (أو مواد أخرى) بناءً على كثافاتها، وعادةً ما تستخدم الماء كوسط فصل. المبدأ الأساسي بسيط ولكنه فعال للغاية: المواد الأكثر كثافة من الوسط السائل تغرق، بينما تطفو المواد الأقل كثافة. تُعد هذه العملية بالغة الأهمية لفصل تيارات البلاستيك المختلطة، وهو تحدٍّ شائع في نفايات ما بعد الاستهلاك وما بعد الصناعة.

على سبيل المثال، في دفعة مختلطة من زجاجات PET (بولي إيثيلين تيريفثالات) وأغطيتها وملصقاتها المصنوعة من PP/PE (بولي بروبيلين/بولي إيثيلين)، يغرق PET، لكونه أكثر كثافة من الماء. على العكس، يطفو PP وPE، لكونهما أقل كثافة من الماء. هذا يسمح بفصلهما بفعالية، وهي خطوة أساسية في إنتاج مواد خام مُعاد تدويرها عالية الجودة.

كيف يعمل خزان الفصل بالغرق والطفو؟ علم الفصل

عملية تشغيل خزان الفصل بالوعة العوامة يستفيد من مبدأ أرخميدس. لنبدأ بتحليل سير العمل النموذجي:

- إدخال المواد: تُغذّى رقائق البلاستيك المُعالَجة مسبقًا - والتي غالبًا ما تكون مغسولة ومُقطّعة - في أحد طرفي الخزان. تُعدُّ خطوة المعالجة المسبقة هذه بالغة الأهمية لأنها تضمن أن تكون المادة ذات حجم مناسب ونظافتها لضمان فصل مثالي.

- الغمر والتحريك: عند دخول المواد البلاستيكية المختلطة إلى الخزان المملوء بالماء (أو أحيانًا بمحلول ملحي لضبط الكثافة بدقة)، تُحرّك برفق. هذا يضمن تبليل جميع أسطح جزيئات البلاستيك وخروج الهواء المحبوس، مما يمنع سحب المواد الأقل كثافة بشكل مصطنع إلى الأسفل.

- الفصل القائم على الكثافة:

- جزء الغرق: المواد ذات الكثافة الأكبر من كثافة السائل الفاصل (على سبيل المثال، PET، PVC في الماء) ستغرق تدريجيا إلى قاع الخزان.

- الكسر العائم: المواد التي لها كثافة أقل من كثافة السائل المنفصل (على سبيل المثال، PE، PP في الماء) سوف تطفو على السطح.

- استخراج المواد:

- يتم عادة إزالة المواد العائمة من السطح باستخدام مجاديف دوارة أو ناقل بطيء الحركة وتوجيهها إلى مجرى تفريغ منفصل.

- يتم جمع المواد الغارقة من قاع الخزان، غالبًا عن طريق ناقل لولبي أو ناقل سحب، ونقلها إلى نقطة التفريغ الخاصة بها.

- إدارة المياه: حديث خزانات فصل الغاطس والطفو غالبًا ما تتضمن أنظمة تدوير وترشيح المياه. هذا لا يوفر الماء فحسب، بل يزيل أيضًا الملوثات الدقيقة، مما يحافظ على كفاءة عملية الفصل ونظافة الماء.

اقتراح الرسم التخطيطي: (تخيل هنا رسمًا تخطيطيًا مبسطًا للمنظر الجانبي، يوضح الخزان مع نقطة تغذية، ومستوى الماء، والبلاستيك العائم الذي يتم كشطه من الأعلى بواسطة مجاديف، والبلاستيك الغارق الذي يتم جمعه بواسطة ناقل لولبي في الأسفل. تشير الأسهم إلى تدفق المواد ودوران المياه.)

مخطط سير العمل المبسط:

[تغذية رقائق البلاستيك المختلطة] --> [خزان الغرق والطفو (وسط الماء)] --> [منطقة التحريك] | |--> [إزالة البلاستيك العائم (مثل البولي إيثيلين والبولي بروبيلين) بواسطة المجاديف/المكاشط] --> [تفريغ جزء الغرق] | |--> [جمع البلاستيك الغاطس (مثل البولي إيثيلين تيرفثالات والبولي فينيل كلوريد) بواسطة الناقل] --> [تفريغ جزء الغرق] | `--> [نظام إعادة تدوير المياه والترشيح]

المكونات الرئيسية واعتبارات التصميم

قوي خزان الفصل بالوعة العوامة يتضمن عادة:

- جسم الخزان الرئيسي: مصنوعة من مواد متينة مثل الفولاذ المقاوم للصدأ لمقاومة التآكل والتآكل.

- مجرى التغذية/الناقل: لإدخال المواد بشكل متحكم.

- المحركات/المحركات (اختياري ولكن موصى به): لضمان الترطيب والفصل الكامل.

- مكشطات السطح/المجاديف: لإزالة الكسر العائم.

- آلية التفريغ السفلي: ناقلات لولبية أو سلاسل سحب لاستخراج الجزء الغارق.

- منافذ دخول وخروج المياه: للتعبئة والصرف وإعادة التدوير.

- نظام الترشيح: للحفاظ على جودة المياه وخفض تكاليف التشغيل.

- لوحة التحكم: لإدارة سرعات المحرك، وتدفق المياه، وغيرها من المعلمات التشغيلية.

التطبيقات في صناعة إعادة تدوير البلاستيك

خزانات فصل الغاطس والطفو متعددة الاستخدامات ويمكن استخدامها في مختلف مجالات إعادة تدوير البلاستيك:

- إعادة تدوير زجاجات PET: حجر الأساس لفصل رقائق زجاجات PET (الحوض) عن أغطية وملصقات PP/PE (العائمة).

- إعادة تدوير البولي أوليفينات المختلطة: فصل البولي إيثيلين عن البولي بروبيلين (PP) باستخدام وسط سائل بكثافة بينهما (وهو أقل شيوعًا، وعادةً ما تُضبط الكثافة للماء). والأكثر شيوعًا هو فصل البولي أوليفينات (PE، PP) عن الملوثات مثل البوليسترين (PS)، أو البولي فينيل كلوريد (PVC)، أو الأكريلونيتريل بوتادين ستايرين (ABS).

- إعادة تدوير البلاستيك الصلب: فصل المواد من البالات المختلطة من مواد التغليف الصلبة بعد الاستهلاك.

- نفايات المعدات الكهربائية والإلكترونية (WEEE) البلاستيكية: فصل أنواع البلاستيك المختلفة الموجودة في النفايات الإلكترونية.

- إعادة تدوير البلاستيك في السيارات: عزل البوليمرات المحددة من مكونات السيارات المقطعة.

مزايا عملية إعادة التدوير الخاصة بك

الاستثمار في الجودة العالية خزان الفصل بالوعة العوامة يقدم العديد من الفوائد لمعيدي التدوير الصناعيين:

- تحسين نقاء المواد المعاد تدويرها: يحقق مستويات عالية من الفصل، مما يؤدي إلى منتج نهائي أكثر قيمة.

- زيادة الكفاءة: يقوم بأتمتة خطوة الفصل الحرجة، مما يقلل من العمل اليدوي ووقت المعالجة.

- الفعالية من حيث التكلفة: تكاليف تشغيلية منخفضة نسبيًا، خاصة مع أنظمة إدارة المياه الفعالة.

- براعه: يمكنها التعامل مع مجموعة واسعة من أنواع البلاستيك ومستويات التلوث.

- الامتثال البيئي: يساهم في تحسين استخدام الموارد ويقلل من عبء مكبات النفايات.

- تحسين الربحية: تتمتع المواد المعاد تدويرها ذات النقاء الأعلى بأسعار أفضل في السوق.

اختيار خزان الفصل بالوعة العائمة المناسب لاحتياجاتك

عند النظر في خزان الفصل بالوعة العوامةينبغي على المشترين الصناعيين تقييم:

- سعة الإنتاج: مطابقة قدرة معالجة الخزان مع حجم منشأتك.

- أنواع المواد: ضمان تحسين التصميم للبلاستيك المحدد الذي تقوم بمعالجته.

- كفاءة الفصل: ابحث عن التصميمات التي تقلل من التلوث المتبادل بين أجزاء الحوض والطفو.

- البصمة والتكامل: كيف سيتناسب الخزان مع خط إعادة التدوير الحالي لديك؟

- استهلاك المياه وإدارتها: تعتبر ميزات الحفاظ على المياه والترشيح أمرًا بالغ الأهمية للعمل المستدام.

- جودة البناء والمتانة: اختر المواد القوية والهندسة المثبتة.

- متطلبات الصيانة: سهولة الوصول للتنظيف واستبدال الأجزاء.

رومتو: شريكك في تكنولوجيا الفصل المتقدمة

في Rumtoo، نحن متخصصون في توفير أحدث آلات إعادة تدوير البلاستيك، بما في ذلك الآلات عالية الكفاءة خزانات فصل الغاطس والطفوتُولي تصاميمنا الأولوية للموثوقية ودقة الفصل وكفاءة التشغيل لمساعدة منشأتكم على تعظيم قيمة موادكم المُعاد تدويرها. نحن نُدرك تمامًا تفاصيل إعادة تدوير البلاستيك، ونُقدم لكم المشورة بشأن أفضل الحلول التي تُلبي متطلباتكم التشغيلية الخاصة.

لمعرفة المزيد عن مجموعتنا من حلول الفصل وكيف يمكنها أن تفيد عملياتك، يرجى استكشاف خزان الفصل بالوعة العوامة الصفحة أو اتصل بفريق المبيعات الفنية لدينا للحصول على استشارة.

خاتمة

ال خزان الفصل بالوعة العوامة ليست مجرد معدة، بل هي حجر الأساس لإعادة تدوير البلاستيك بفعالية. فمن خلال فصل البلاستيك بكفاءة بناءً على كثافته، تلعب هذه الخزانات دورًا حيويًا في تحويل النفايات البلاستيكية المختلطة إلى مواد خام قيّمة وعالية النقاء جاهزة للاستخدام لاحقًا. بالنسبة لمحترفي إعادة التدوير الذين يسعون إلى تحسين جودة إنتاجهم وكفاءتهم التشغيلية، فإن فهم تقنية الغرق والطفو المناسبة والاستثمار فيها يُعدّ خطوةً واضحةً نحو مستقبل أكثر ربحيةً واستدامة.