Eco Champions: Plastic Pelletizers for a Sustainable Future

প্লাস্টিক Pelletizers

From Waste to Wonder: Plastic Pelletizers in Action

Turn Trash into Treasure: The Power of Plastic Pelletizers

plastic pelletizer machine transforming plastic flakes into pellets

Pelletize Your Profits: Boost Recycling with Efficiency

ক্যাটাগরি প্লাস্টিক Pelletizers

পোস্ট করা হয়েছে

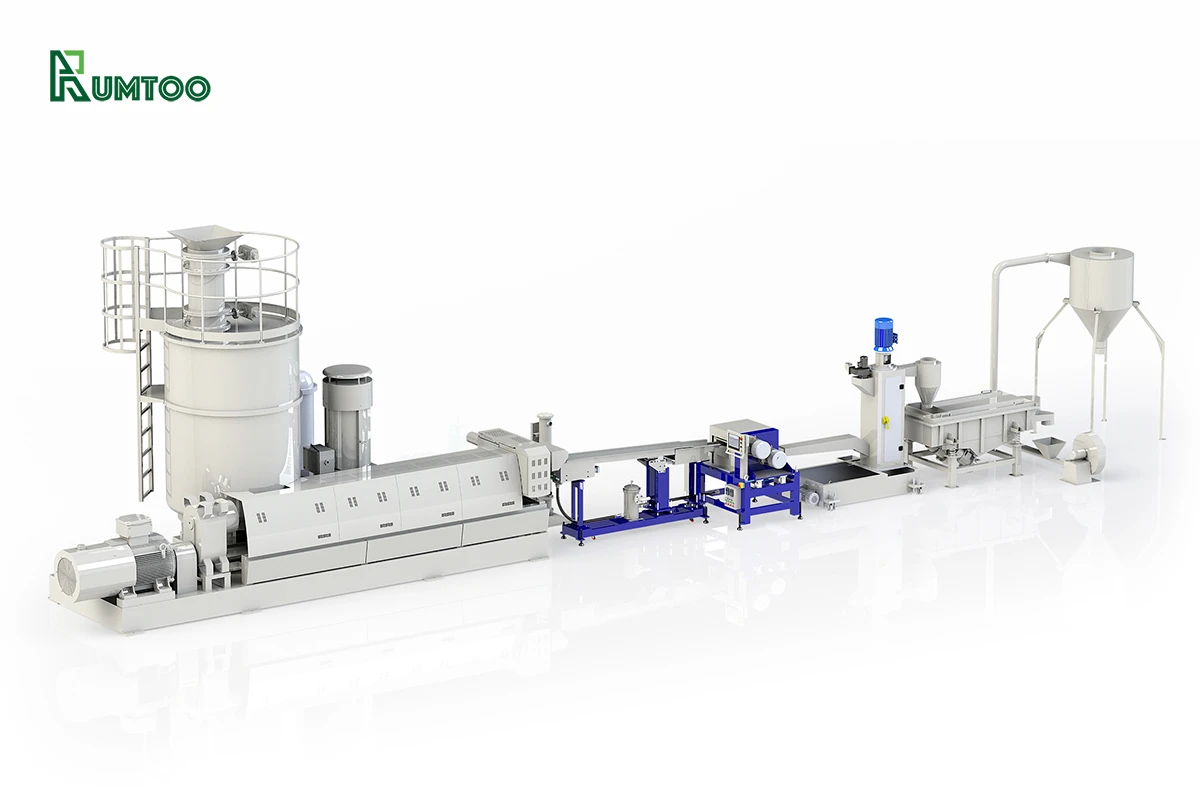

Discover the Twin-Screw Plastic Extruder/Pelletizer, an advanced, high-speed, co-rotating machine designed for efficient and reliable plastic recycling.

ক্যাটাগরি প্লাস্টিক Pelletizers

পোস্ট করা হয়েছে

Explore the advanced features of Single-Screw Plastic Pelletizing Machines, designed for efficient and high-quality plastic recycling. Equipped with Heat Wave Stabilization™ for uniform heat distribution.

ক্যাটাগরি প্লাস্টিক Pelletizers

পোস্ট করা হয়েছে

Explore the Water Ring Pelletizer for Clean PP and PE Plastic Film/Woven Bags, an advanced recycling solution that combines multiple processes into a single stage for high-quality pellets.

ক্যাটাগরি প্লাস্টিক Pelletizers

পোস্ট করা হয়েছে

Dive into the workings of the Machine for Pelletizing Rigid PP and HDPE Plastic Flakes, a revolutionary tool in plastic recycling, transforming flakes into high-quality pellets.

ক্যাটাগরি প্লাস্টিক Pelletizers

পোস্ট করা হয়েছে

An in-depth look at the PET Plastic Flake Single Screw Pelletizer, its working principle, and its role in sustainable plastic production.

ক্যাটাগরি প্লাস্টিক Pelletizers

পোস্ট করা হয়েছে

We provide complete process piping capabilities for industrial from pulp and paper.