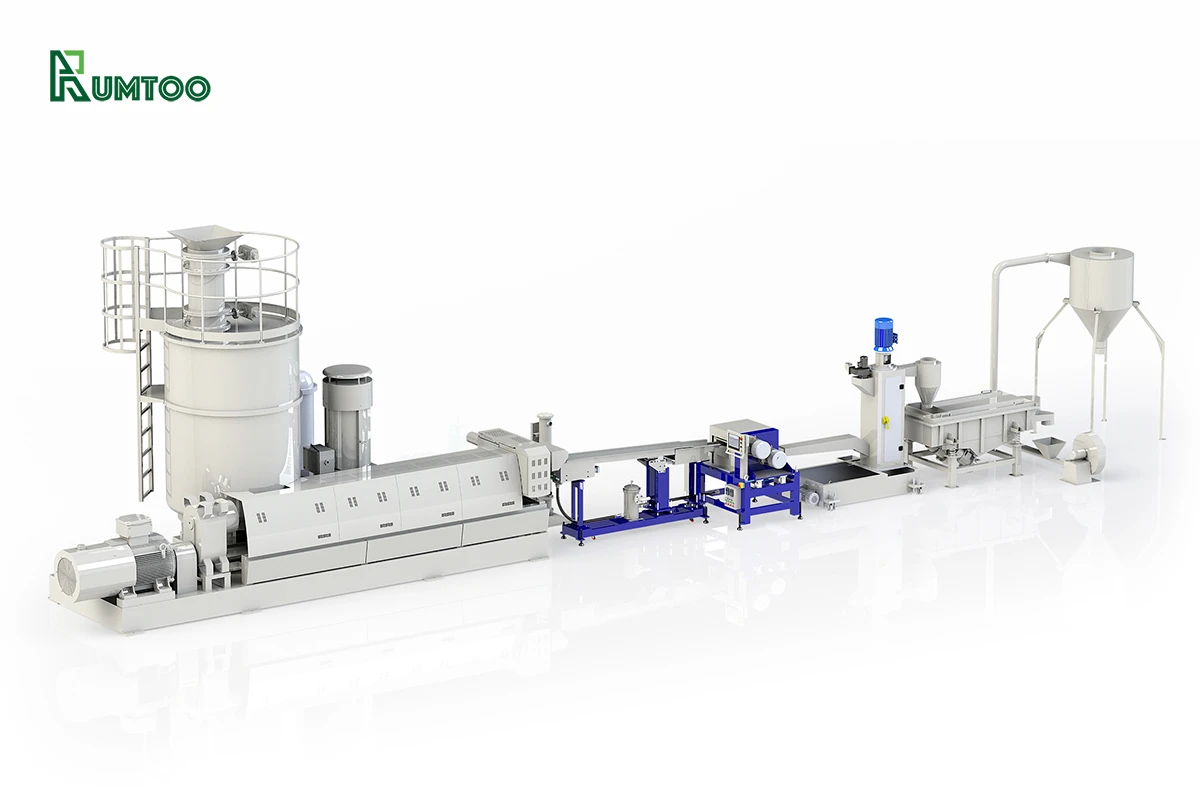

Create High-Value, Uniform Plastic Pellets

Our advanced plastic pelletizing lines are the final step in transforming recycled plastic waste into a valuable, consistent, and reusable raw material. We engineer complete systems for compounding, modifying, and pelletizing a wide range of polymers.

Design Your Pelletizing Line

Choosing The Right Pelletizing System

The ideal technology depends on your material type, output requirements, and operational preferences. We specialize in two primary, highly efficient systems.

Water Strand Pelletizing Line

A classic, robust, and cost-effective method ideal for a wide variety of polymers, especially those sensitive to temperature changes.

- Process: Molten plastic is extruded into strands, cooled in a water bath, and then cut into pellets by a granulator.

- Bedst til: PET, Polystyrene (PS), and highly-filled or reinforced compounds.

- Advantage: Simple operation, easy to clean, and versatile for lab or large-scale production.

Water-Ring Pelletizing Line

A more automated and compact system that cuts pellets at the die face, ideal for high-volume production of polyolefins.

- Process: Blades rotate at the die face, cutting pellets which are instantly quenched and transported by a circulating water ring.

- Bedst til: PE, PP, and other materials with lower melt viscosity.

- Advantage: Produces uniform, spherical pellets, requires less floor space, and is highly automated.

Se vores system i aktion

Watch a complete walkthrough of one of our advanced plastic pelletizing lines, from raw material to final, high-quality pellets.

Engineered for Ultimate Pellet Quality

Every component is selected to ensure the purity, consistency, and value of your final product.

-

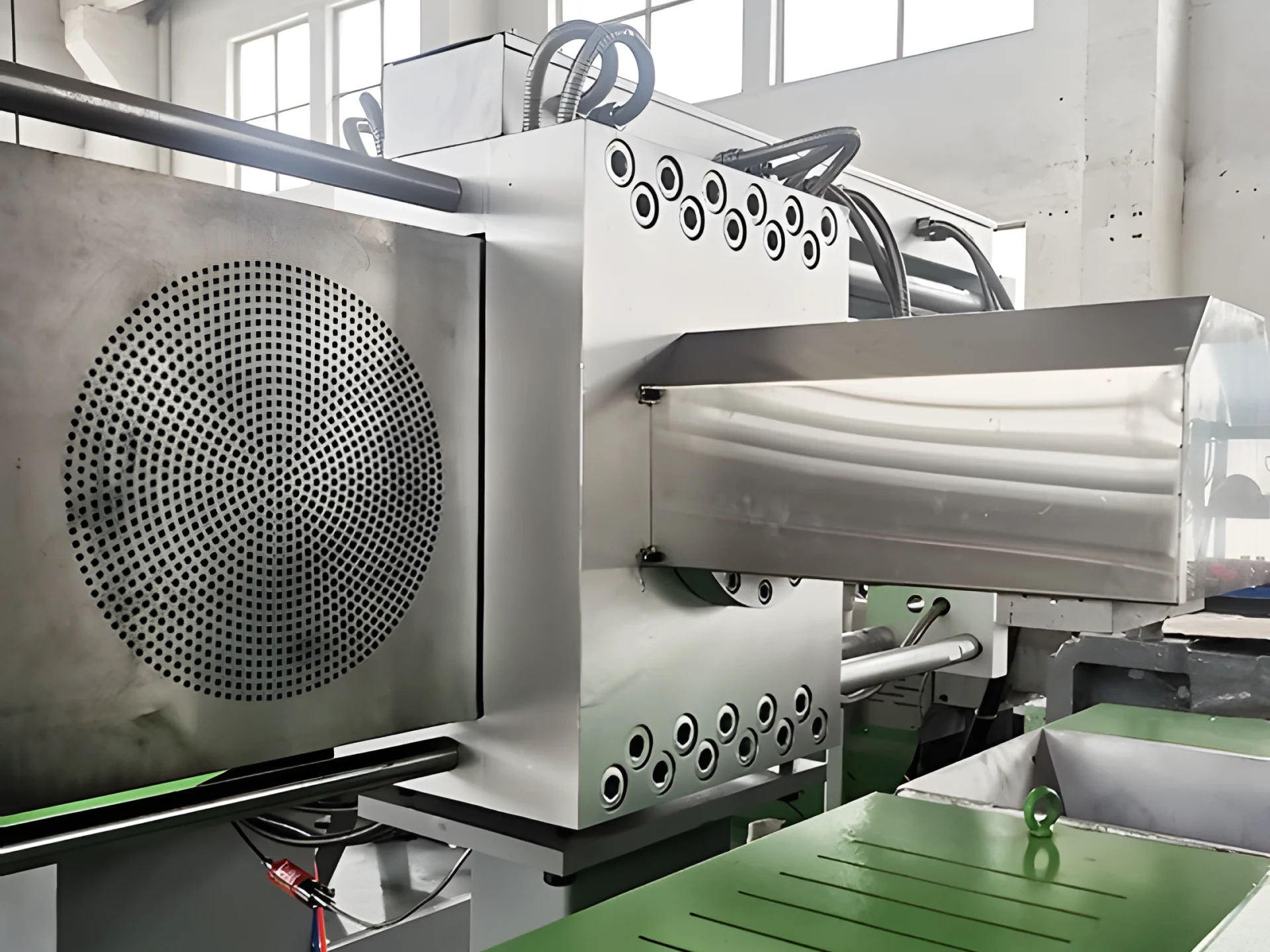

Continuous Melt Filtration

Automatic screen changers remove contaminants without interrupting production, ensuring a pure melt stream.

-

Efficient Dewatering

A vertical centrifugal dryer rapidly removes surface water from the pellets, preparing them for classification and storage.

-

Pellet Classification

A vibrating screen classifies pellets by size, removing oversized or undersized particles for a highly uniform final product.

-

Precision Twin-Screw Extruder

Provides excellent mixing and dispersion for compounding applications, ensuring homogeneity of additives and fillers.

Achieve Premium Pellet Quality

Our systems produce clean, uniform, and highly marketable pellets from a wide range of input materials.

PE Pellets

Plastic Film Pellets

PVC & Hard Plastic Pellets

Ready to Produce Premium Plastic Pellets?

Contact our experts to discuss your specific material and application. We will design a custom pelletizing or compounding line to meet your goals for quality and throughput.

Get a Custom System Quote