In the world of plastic recycling, water is an indispensable resource. From washing flakes to separating materials, its role is crucial. However, this process generates significant volumes of wastewater laden with contaminants. For modern recycling facilities aiming for sustainability and operational excellence, treating this water isn’t just a regulatory hurdle—it’s a commercial imperative.

At Rumtoo, we understand that an effective water treatment system is the heart of a clean and profitable recycling operation. One of the most powerful technologies in our arsenal is Dissolved Air Flotation (DAF). This article explores how DAF technology masterfully removes three key culprits in wastewater contamination: Suspended Solids (SS), Fats, Oils, and Greases (FOG), and Biochemical Oxygen Demand (BOD).

Understanding the Contaminants: What are SS, FOG, and BOD?

Before we delve into the solution, let’s clarify the problem. The wastewater from plastic recycling is a complex mixture, but three primary indicators of pollution are:

- Suspended Solids (SS): These are fine particles of plastic, labels, dirt, and other insoluble materials that remain suspended in the water after the initial washing stages. High SS levels make water cloudy, can damage equipment, and are a major pollutant in discharge water.

- Fats, Oils, and Greases (FOG): These contaminants often come from residual contents in post-consumer plastic containers (e.g., food packaging, bottles). FOG can cause blockages in pipes, create unpleasant odours, and severely disrupt downstream water treatment processes.

- Biochemical Oxygen Demand (BOD): BOD is a measure of the amount of dissolved oxygen required by aerobic biological organisms to break down organic matter present in water. High BOD indicates a significant level of organic pollution (like glues, food residues, and sugars), which can deplete the oxygen in natural water bodies, harming aquatic life.

Effectively removing these three is the benchmark of a high-performing water treatment system.

The Mechanics of Purity: How Does Dissolved Air Flotation Equipment Work?

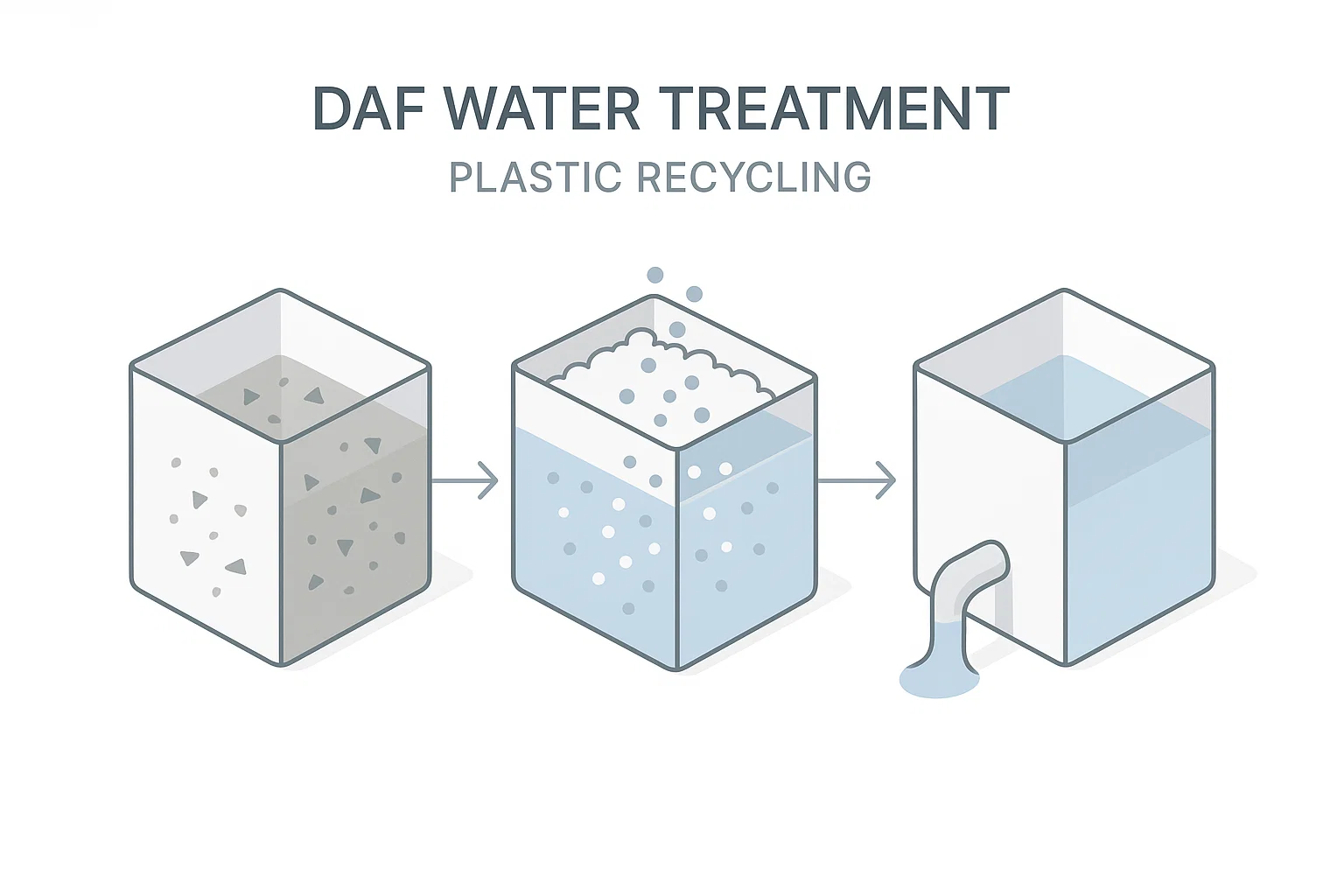

Dissolved Air Flotation (DAF) is an elegant and highly efficient water clarification technology. Its principle is simple: use microbubbles to lift contaminants to the surface, where they can be skimmed off.

The process involves pressurising a portion of the treated water and saturating it with dissolved air. When this pressurised water is released back into the main flotation tank at atmospheric pressure, the dissolved air precipitates out of the solution as millions of microscopic bubbles (typically 30-50 microns in diameter).

These microbubbles attach to the suspended solids and FOG particles, reducing their overall density and causing them to float to the surface. This forms a layer of sludge, or “float,” which is then mechanically scraped away. Heavier solids that do not float will settle at the bottom of the tank and are removed separately.

Rumtoo DAF System Workflow

To illustrate this, here is a simplified workflow of a typical DAF unit in a plastic recycling facility:

| Step 1: Influent & Coagulation/Flocculation |

| ↓ |

| Wastewater enters the system. Coagulants and flocculants are dosed to destabilise fine particles and encourage them to clump together (form ‘flocs’). |

| ↓ |

| Step 2: Contact & Bubble Attachment |

| ↓ |

| The flocculated water enters the DAF tank where it mixes with the stream of water containing microbubbles from the air saturation vessel. |

| ↓ |

| Step 3: Flotation & Separation |

| ↓ |

| Microbubbles adhere to the flocs, lifting them to the surface to form a sludge layer. Heavy solids sink to the bottom. |

| ↓ |

| Step 4: Sludge Skimming & Effluent Discharge |

| ↓ |

| A mechanical skimmer removes the surface sludge for dewatering/disposal. Clarified water (effluent) is discharged from the bottom of the tank. |

This continuous process ensures a consistent output of clean water, ready for reuse within your facility or for safe discharge, in line with environmental regulations.

Why DAF is the Superior Choice for Plastic Recycling

While various water treatment methods exist, Dissolved Air Flotation equipment offers distinct advantages for the specific challenges of plastic recycling wastewater. Its ability to target low-density particles like plastic fines and oils makes it particularly effective.

Here’s how DAF compares to other common treatment methods for removing our key contaminants:

Performance Comparison: DAF vs. Other Treatment Methods

| Treatment Method | SS Removal Efficiency | FOG Removal Efficiency | BOD Removal Efficiency | Key Considerations |

| দ্রবীভূত বায়ু ভাসমান (DAF) | > 95% | > 97% | 40-70% | Excellent for low-density solids and FOG. Highly efficient and compact. |

| Sedimentation / Clarification | 40-60% | 50-70% | 20-40% | Ineffective for oils and low-density plastic fines that do not settle easily. |

| Media Filtration | > 90% | < 40% | < 30% | Prone to rapid clogging from high FOG and SS loads without pre-treatment. |

| Biological Treatment (e.g., MBR) | > 98% | > 90% | > 90% | Highly effective but sensitive to FOG shock loading and requires a larger footprint. |

As the chart illustrates, DAF provides an unparalleled level of FOG and SS removal in a single, robust process. While it achieves a moderate BOD reduction, it serves as the perfect pre-treatment step. By removing the bulk of solids and oils, it protects more sensitive downstream systems (like biological treatments), allowing them to operate at peak efficiency. For more insights on integrating DAF systems, explore our article on efficient DAF water treatment for plastic recycling.

Choosing the Right DAF System for Your Operation

Selecting the correct Dissolved Air Flotation equipment is crucial. The size and configuration depend on several factors:

- প্রবাহ হার: The volume of wastewater your facility produces per hour.

- Contaminant Loading: The typical concentrations of SS, FOG, and BOD in your influent.

- Discharge Requirements: The water quality standards you need to meet for reuse or discharge.

- স্থানের প্রাপ্যতা: The physical footprint available for the installation.

At Rumtoo, we don’t just sell machinery; we provide solutions. Our team of engineers works closely with you to analyse your specific needs and recommend a DAF system that delivers optimal performance and the best return on investment.

Conclusion: A Clear Path to Sustainable Recycling

In a competitive market, efficiency and sustainability are no longer optional. A high-performance water treatment system is fundamental to reducing operational costs, ensuring environmental compliance, and enhancing your brand’s reputation.

DAF technology offers a proven, powerful, and cost-effective solution for clarifying plastic recycling wastewater. By effectively removing suspended solids and fats, oils, and greases, it paves the way for greater water circularity and a healthier bottom line.

Ready to see how Dissolved Air Flotation equipment can transform your facility’s water treatment process? Contact the experts at Rumtoo today to discuss your requirements and discover a clearer path to profitability and sustainability.